At Schaumburg Specialties, we’ve been making our clients’ custom build visions a reality for over 40 years.

With our knowledge, experience and expertise, coupled with cutting edge technology, we’ve produced countless unique custom build solutions to complex production challenges, often within tight deadlines.

We are experts in the specific requirements of the commercial baking, meat production, meal kit, aerostructure manufacturing and pet food sectors – to name but a few – and we understand that the needs of each industry can be vastly different from one another.

We always take a personalized approach and work with our customers to ensure they receive a custom build and/or installation solution that’s tailormade for their business.

Read on to discover all about the Top 5 projects we’ve worked on for five very different companies – and be sure to let us know which one is your favorite!

Project 1: Specialized Handling Carts For A World Leading Aerostructure Manufacturer

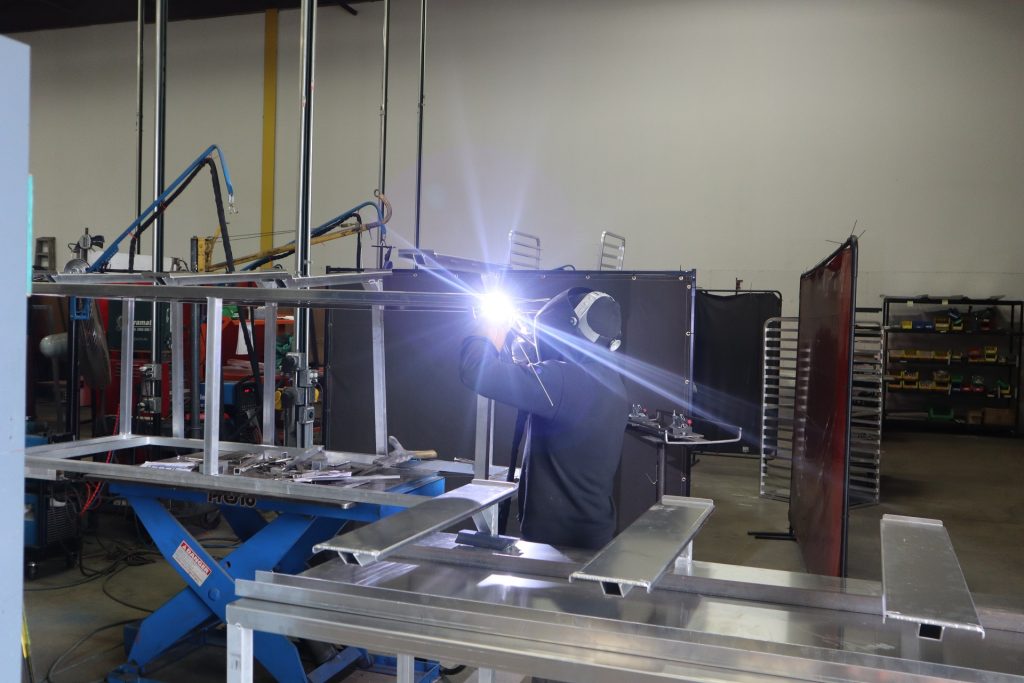

The team at Schaumburg Specialties was approached by a global aerospace giant to custom design and build strong, sturdy, specialist handling carts that could withstand high temperatures for the bladders (inflatable structures) that they use to manufacture composite aircraft parts such as wings and fuselages.

In addition, we were also asked to build specialized handling carts for a world leading aircraft manufacturer that would be used to handle and transport the long, thin structural stringers that run lengthwise along an aircraft to provide rigidity and support.

Configuring rack dimensions so that the client is able to optimise their workspace is a big part of what goes into our custom build work, and in this case, the racks needed to be specially configured to fit all the different stages of our client’s aircraft manufacturing process.

Armed with only a few simple PowerPoint drawings, we custom fabricated several 65 ft-long bladder carts and several stringer carts for the company.

The carts were all transported in modular form to its manufacturing facility in North Carolina, where they were then assembled and put to work straight away on our client’s production line, helping build world-beating aerospace structures.

Project 2. Storage Racks For A Leading Prepared Meals Company

America’s No.1 meal kit provider came to us with a rough but very specific custom build design idea in mind.

The team had some sketches of a unique rack they wanted to store, transport and quickly and easily identify the large plastic tubs that they use to hold ingredients and prepped food portions.

So we brought their design ideas to life!

We built a custom storage rack from premium quality American-made stainless steel (to meet sanitation requirements) that could safely and securely hold 12 tubs at a time, with clear dividers and space for identification labels.

This allowed staff to quickly and easily identify which tub held what, thereby streamlining our client’s working operations and boosting its efficiency and productivity.

Project 3. Heavy Duty Racks For Ed Miniat

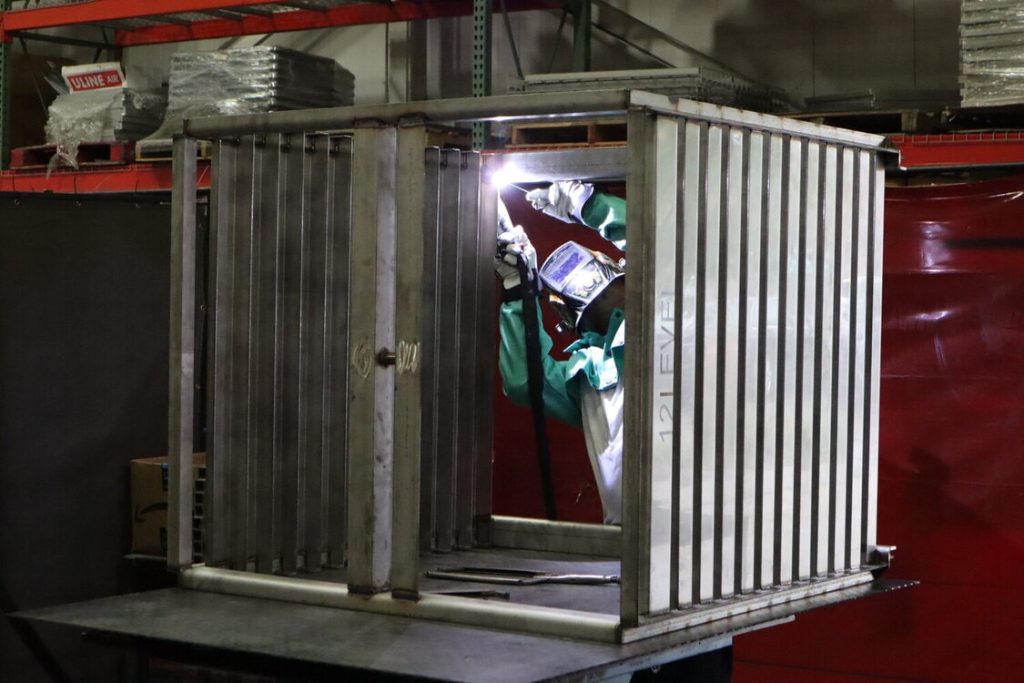

Our expert design engineers and fabricators were tasked by leading meat production company Ed Miniat to custom build several heavy duty racks and grids for use in its large scale cooking of prepared proteins using the sous vide method.

The team visited the Ed Miniat factory in Chicago and saw the machinations of sous vide cooking (whereby a rack full of vacuum-sealed protein product is lifted by a crane and immersed in a water bath at just below boiling point) for themselves.

They knew that the racks we built had to be super sturdy and strong, not only to withstand high cooking temperatures and water immersion but also to maintain their form when being lifted by the cranes.

Back at Schaumburg HQ, our design engineers, metal formers and welders got to work!

They designed and fabricated 35 12-level racks, with 12 wire grids (one per shelf) that each had upturned ends and two heavy duty bars across the top that would stop the meat pouches floating off the rack during cooking or dropping off the rack when being transported around Ed Miniat’s facility.

Once the custom build project had been delivered to our client, they were able to get on with their mass food production, safe in the knowledge that they were using top quality and high performing racks that would stand the test of time.

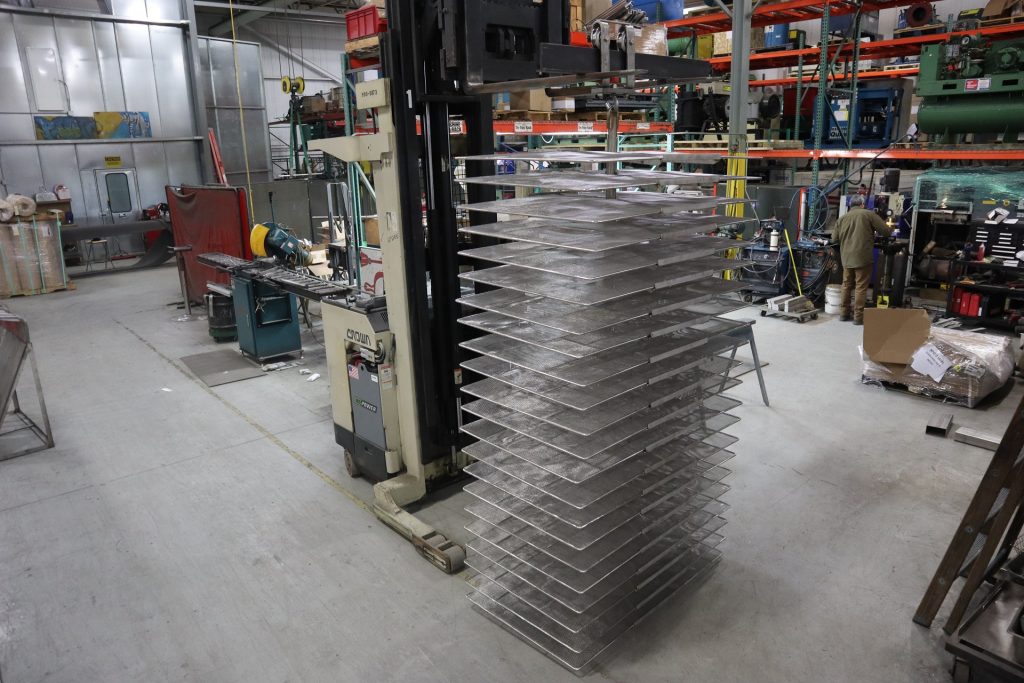

4. Unique Tree Rack For Redbarn Pet Products

Hearing about Schaumburg Specialties’ famous reputation for the highest quality, best performing racks in the food production industry, this premium pet food manufacturer approached us with a few simple drawings and samples and asked us to fabricate their unique ‘tree rack’ from the ground up – and to a very tight deadline!

Our experts quickly got to work designing and fabricating 36 tree racks with approximately 22 levels of screens (or trays) made of welded wire mesh that would hold raw ground meat to make pet food and treats.

The size of the holes in the wire mesh were designed in such a way that none of the meat pieces would fall through during preparation or cooking.

Our ingenious designers also put a central pole down the middle of each rack, which had grooves from top to bottom that the trays could easily slot in and out of. This made emptying and refilling and reattaching the trays a breeze for Redbarn’s workers!

All this custom work was carried out with the greatest skill and efficiency, to an extremely tight timeline – and our client was delighted with the results!

5. Somengil MultiWasher Install At Omaha Steaks

Omaha Steaks, the company that pioneered steak delivery and food service in the United States, contacted our team with a very specific problem – how to get its food production equipment clean and sanitized in a far quicker time.

Delivery of four million orders to three million customers across the US every year meant that the company’s production line needed to be extremely efficient – but because they were employing the old-fashioned art of hosing down their equipment manually, getting the equipment clean was taking far too long and causing the company to lose precious time and profits.

One of Omaha Steaks’ team had found the Somengil rack MultiWasher on our website and were attracted to the unparalleled cleaning and sanitation capabilities, as well as the spectacular efficiency and reduced energy and water usage, of this powerful machine (read more about how you can revolutionize your cleaning processes with the Somengil MultiWasher).

Once ordered, our own Eric Schaumburg drove the 600 miles to Snyder, Nebraska to oversee the delivery of the MultiWasher and there he met Somengil’s technician to assist in the assembly and installation of the MultiWasher to the exact specifications and requirements of Omaha Steaks’ production line and premises.

It was just what Omaha Steaks needed to boost the productivity of its working operations and meet the demand of its millions of hungry customers!

Get Started with Your Own Custom Project

We delivered awesome results for all these customers and now we want to do the same for you!

If you have a custom build idea in mind or you have a specific production challenge that requires a tailor made solution, we’re here to help.

To get started with your own project with Schaumburg Specialties, and to bring your design ideas to life, contact us so that we can get a clear understanding of your requirements. We’ll take it from there!