| Client: | Omaha Steaks |

| Industry: | Food Manufacturing |

| Location: | Omaha |

The Client

Founded in 1917, the company calls itself ‘America’s Original Butcher’ and has a rich history of meat delivery. In 1952, they were the first company to start selling steaks via magazine ads and direct-mail flyers, and today they offer a large selection of pork, poultry, skillet meals, seafood, side dishes and desserts (as well as their famous steaks!) online, in retail stores, via direct mail and of course through their food service.

Founded in 1917, the company calls itself ‘America’s Original Butcher’ and has a rich history of meat delivery. In 1952, they were the first company to start selling steaks via magazine ads and direct-mail flyers, and today they offer a large selection of pork, poultry, skillet meals, seafood, side dishes and desserts (as well as their famous steaks!) online, in retail stores, via direct mail and of course through their food service.

Omaha Steaks also offers ready-to-serve and easy-to-prepare gourmet foods and employs 1500 staff to get four million orders to three million customers every year.

Needless to say, we were delighted to lend our skills towards helping such a time-honoured company as Omaha Steaks!

The Omaha Steaks factory working to produce mouth-watering meat

The Omaha Steaks factory working to produce mouth-watering meat

The Challenge

With so many offerings available to clients, Omaha Steaks runs a tight ship and requires quick turnaround times for their food manufacturing equipment. When preparing meat products too, it’s paramount that the equipment being used is clean and sanitised.

Unfortunately, Omaha Steaks were still having to employ the old-fashioned art of hosing down their trays, bins and tubs in sinks, out in the open. Getting the equipment clean was taking far too long, causing the company to lose precious time, and in the long run, profits. They desperately needed to find a way to get their equipment clean and sanitised in a timely fashion.

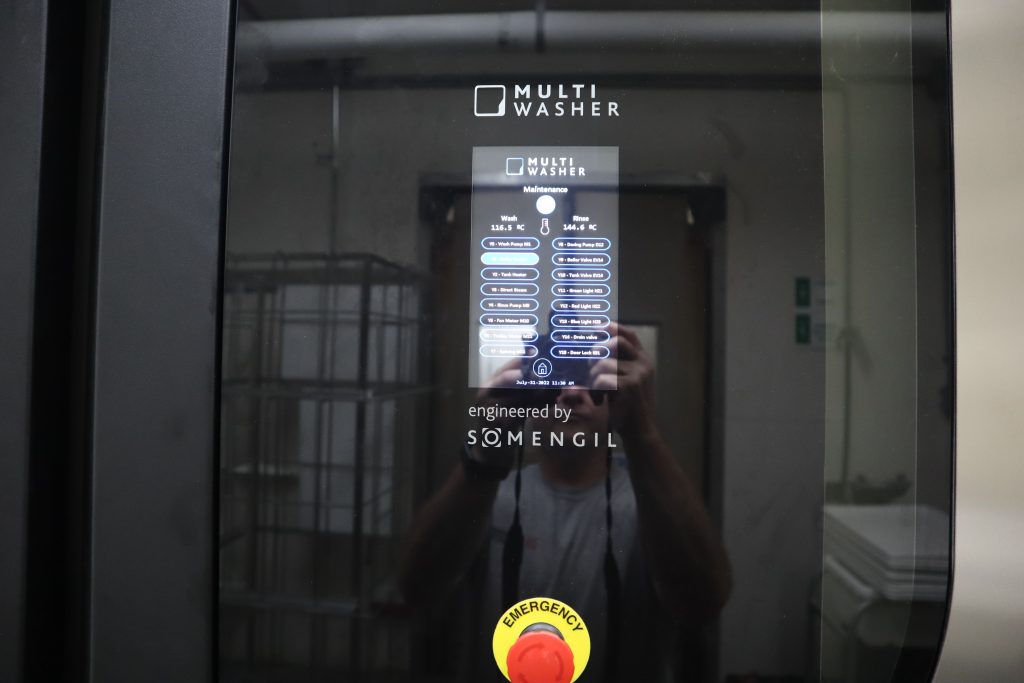

One of Omaha Steaks’ staff members found the Somengil rack multiwasher on our website. They were attracted to the reduced water and detergent usage of the washer and its sanitation capabilities.

An Omaha Steaks worker hoses down their equipment with detergent and water to clean it

Our Solution

By purchasing a Somengil rack multi washer, Ohama Steaks were able to ditch the old-fashioned way of hosing down their food processing equipment with soap and water and can now ensure clean, sanitised trays, bins and tubs for their many production lines.

And because the washer can perform 40-50 cycles per shift, Omaha Steaks staff don’t have to spend lots of time ensuring equipment is cleaned properly. They can leave it all to the Somengil multiwasher and get on with producing wonderful food for their three million – and counting – loyal customers!

Watch the powerful Somengil multiwasher in action

The Installation Of The Multiwasher

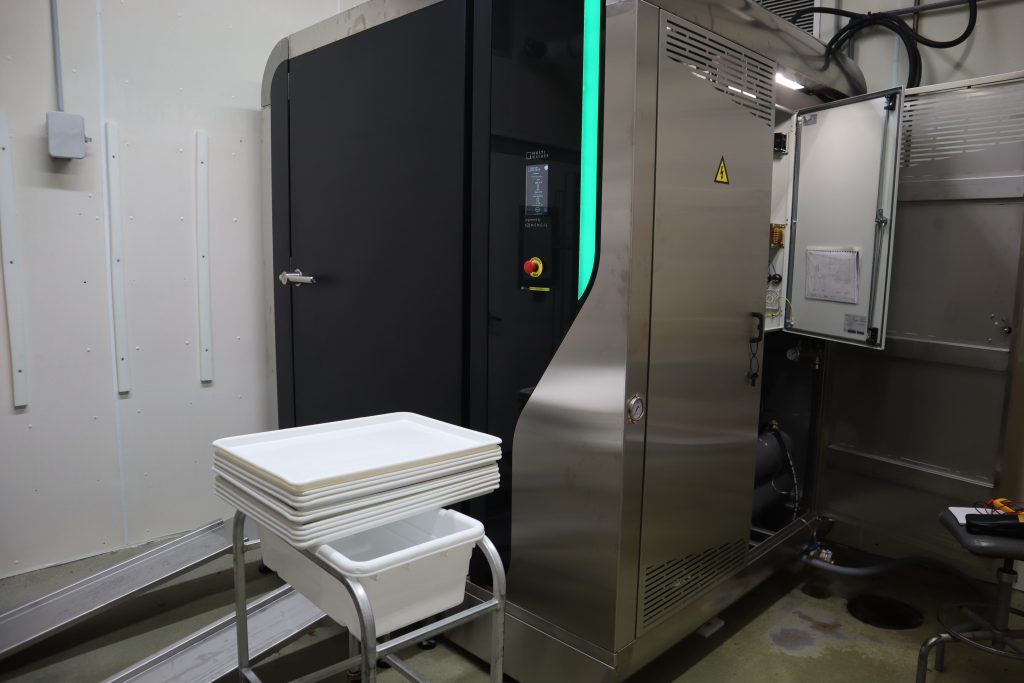

The washer was delivered from Somengil’s factory in Portugal fully assembled (but not sealed). Once it arrived at Omaha Steaks, it needed to be disassembled because it couldn’t fit through the doorways of the wash room as one unit.

A multiwasher like the Somengil model can wash carts, trollies, racks and utensils. Huge trollies are loaded up outside the washer and wheeled up specially made ramps into a cage, which rotates with the trolley inside.

There are three steps to the washer’s cycle, which lasts approximately seven to eight minutes.

- Firstly, a high-pressure hot water spray containing detergent (which is auto-metred by a dosing pump) washes the equipment, which is then heated to a sanitising temperature of 185 degrees Fahrenheit for approximately 60 seconds.

- The equipment is then rinsed with fresh, clean water and finally, the cage inside the washer is rotated at a speed of around 70-80 rpm to spin and dry the equipment inside.

- When the washer is opened and the trolley is taken out into room temperature, the equipment dries instantly because of the high temperature inside the washer.

Joel and Eric from the Schaumburg Specialties team worked with Omaha Steaks – and Somengil, who sent a technician to Omaha Steaks HQ – to install the shiny new washer.

Eric drove the 600 miles to Snyder, Nebraska to oversee the delivery of the multiwasher. There, he met the Somengil technician and assisted in its installation and connection to Omaha Steak’s electric, water and drainage systems.

All in a day’s work for Schaumburg Specialties!

Get Started with Your Own Custom Project

We delivered awesome results for this customer, and now we want to do the same for you. To get started with your own project with Schaumburg Specialties, contact us so that we can get a clear understanding of your requirements. We’ll take it from there!