At Schaumburg Specialties, we know that fully functioning, top-performing equipment is the key to an efficient, productive and successful business. And our customers need that equipment expertly installed and running optimally, day in and day out.

Meticulous set-up of ovens, proofers, rack washers and other equipment to exact manufacturer’s specifications is an integral part of our Equipment Servicing and Maintenance Program. Our expert technicians make sure that production equipment is rapidly and seamlessly integrated into every production line, fully optimized for every client’s working operations and operating at peak performance before we leave their premises.

Since we started the program in March 2024, we’ve embarked on several installation projects for our clients and each one has provided our team with a unique, enjoyable challenge. Read on as we reveal the Top 5 projects we’ve worked on and be sure to let us know which one is your favorite!

Project 1: Oven Install At Pretzilla®

The team at Schaumburg Specialties was approached by our long time valued customer PretzillaⓇ and asked to install and certify six brand new Revent 724 double rack ovens at its premises in Franklin, WI. The company was experiencing rapid expansion and needed the ovens quickly and efficiently installed so it could boost its production capacity to meet increased demand for its legendary bagels. Of course, we were only too happy to step up to the challenge and our technicians quickly got to work.

The Revent ovens – available through Schaumburg Specialties – hold one double pan rack or two single pan racks and come in three large, heavy pieces – the back third of the oven chamber, the front third of the oven chamber (with the door) and the heat exchanger/control panel.

Assembling the ovens

The first part of the challenge was to assemble the ovens in the position that PRETZILLA® required them on its production line. Then, the task was to get them up and running and fully and seamlessly integrated into PRETZILLA® ’s baking operations.

Connecting the ovens to gas/water

Our technicians connected the ovens to the gas and water supplies and checked each oven’s settings – including burner function and gas pressure – to make sure they were functioning efficiently, as well as performing safety checks on the draft and carbon dioxide emissions from the flue and exhaust gases.

We connected the ovens to the gas/water supply

When all the safety checks had been completed, we were able to certify the new ovens and our client could get to work on some test baking that of course turned out to be absolutely delicious! Read more about our great work for PRETZILLA® on our Projects page.

Project 2. Oven & Proofer Installation At JF Heritage Food Company

Some of the Revent ovens installed at the plant (credit: JF Heritage Food Company)

JF Heritage Food Company – who originally made its name producing world-beating sweet and savoury kolaches – was another valued client that was experiencing rapid expansion.

It needed several Revent ovens and proofers installed in a very tight timeframe at its 60,000 sq ft premises in Belton, Texas. It also needed several of our premium quality SHOPCraft racks shipped as quickly as possible.

Luckily, our technicians are well versed in working speedily to our clients’ unique specifications and installed the ovens and proofer at a fearsome pace and completely in harmony with the manufacturer’s specifications and the company’s working operations.

As with all our installation projects, we ensured that the equipment – including the racks! – was working at full throttle, and helping our client to ramp up productivity to meet increased demand, before we left the facility. Another successful day’s graft for our team!

Our SHOPCraft racks in situ at JF Heritage Food Company

(credit: JF Heritage Food Company)

Project 3. Oven Move & Installation At Gabby’s Bakery

Gabby’s, a small commercial bakery based locally in Franklin Park, IL, had recently become part of Gonella Baking Co. when it contacted us in need of some help installing and relocating its ovens.It had had several new lines of frozen dough products added to its portfolio and needed to escalate its productivity quickly.

Our task was to move and relocate an old Dahlen oven to another part of Gabby’s production line, and then install three brand new Revent 703 double double rack ovens that the bakery had purchased from Schaumburg Specialties (double double means that the oven can hold two 18”x 36” sheet pans at a time).

First, we disconnected the old Dahlen oven from the power and used two rented forklifts to attach chains to the oven, lift it, turn it around and relocate it.

The old oven was disconnected and relocated.

The next part of the task was to install the new ovens, which we did by putting the three large pieces of each oven in situ, then standing them up ready to be bolted together and slotted into place.

Our technicians put the oven together.

The final part of the installation was to make sure that the newly installed ovens slotted seamlessly into Gabby’s busy production line. We fired the ovens up and did all the safety checks and ensured that the oven’s flame was working efficiently and effectively.

Before they knew it, Gabby’s had three brand new ovens firing on all cylinders on its production line, markedly increasing production capacity and allowing it to meet the demands of its ever-expanding repertoire!

4. Unique Mezzanine Reinforcement At Alu Bra

At Schaumburg Specialties, we pride ourselves on being versatile – and can turn our hand to almost any request from our valued clients!

So we were delighted when we were asked by Alu Bra Foundry to reinforce an existing mezzanine structure at its premises in neighboring Bensenville, IL. Specializing in high quality castings of brass, bronze and lead-free alloys, Alu Bra is a leading OEM supplier of American made lead free castings and prides itself – as we do – on providing top quality American manufactured equipment to its clients.

The company needed our expertise to reinforce an existing mezzanine at its facility and ensure that the structure was safe and fit for purpose.

Our technicians at work

Our expert technicians got to work and did a great job of fitting three blue beams along the structure, with another supporting beam and supporting columns underneath. At one point, we even brought the columns back to Schaumburg HQ to adjust their length to make sure they fitted perfectly!

And our client was thrilled with the results! All in a day’s work for Schaumburg Specialties.

5. Somengil Multiwasher Install At Omaha Steaks

Omaha Steaks, the company that pioneered steak delivery and food service in the United States, contacted our team with a very specific problem – how to get its food production equipment clean and sanitized far quicker and more efficiently.

Delivery of four million orders to three million customers across the US every year meant that the company’s production line needed to be extremely efficient – but because they were employing the old-fashioned art of hosing down their equipment manually, getting the equipment clean was taking far too long and causing the company to lose precious time and profits.

One of Omaha Steaks’ team had found the Somengil rack Multiwasher on our website and were attracted to the unparalleled cleaning and sanitation capabilities, as well as the spectacular efficiency and reduced energy and water usage, of this powerful machine.

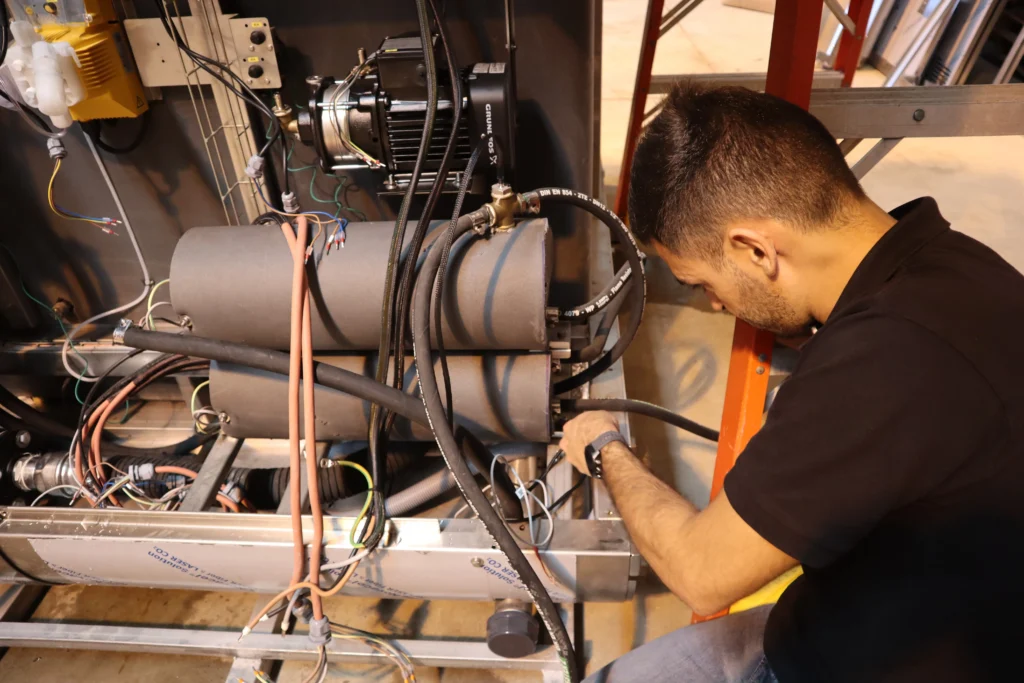

Installation of the Multiwasher

Once ordered, our own Eric Schaumburg drove the 600 miles to Snyder, Nebraska to oversee the delivery of the MultiWasher and there he met Somengil’s technician to assist in the assembly and installation of the Multiwasher to the exact specifications and requirements of Omaha Steaks’ production line and premises. It was just what Omaha Steaks needed to boost the productivity of its working operations and meet the demand of its millions of hungry customers!

Expert Equipment Installation From Schaumburg Specialties

We delivered awesome results for these customers, and now we want to do the same for you. To get your production equipment installed and maintained with Schaumburg Specialties, find out more about our equipment servicing, maintenance and installation program on our website and contact us so that we can get a clear understanding of your requirements. We’ll take it from there!