What Is Stainless Steel?

Stainless steel is no ordinary material. It’s made up of a whole group of iron-based alloys well known for their resistance to corrosion, staining & rusting. This resistance is derived from the presence of chromium, which forms a thin, protective layer of chromium oxide over the metal when it’s exposed to oxygen, preventing further oxidation and making the material ‘stainless’.

Its exceptional corrosion resistance, as well as its strength, durability & aesthetic appeal, means that stainless steel is one of the most highly sought after and widely used materials in metal equipment fabrication across a whole variety of industries – and indeed right here at our workshop in Schaumburg, Illinois.

Composition Of Stainless Steel

The primary component of stainless steel is iron, followed by chromium (at least 10.5% by weight). As previously mentioned, chromium is the main protagonist of stainless steel’s exceptional corrosion resistant properties. Nickel too is often added to enhance ductility, strength and corrosion resistance, while molybdenum improves stainless steel’s resistance to pitting, especially in high chloride environments such as the marine and chemical industries.

Carbon is another key component of stainless steel. However, because it can affect the hardness and tensile strength of stainless steel, it’s often present in varying amounts, depending on the requirements of a specific application. Manganese, silicon and nitrogen may also be added to stainless steel to enhance one or more of its myriad properties.

Types Of Stainless Steel

There are five main types of stainless steel; austenitic, ferritic, martensitic, duplex and precipitation-hardening. The type we use at Schaumburg Specialties to fabricate your metal production equipment will depend on your specific application and your working environment.

Austenitic

This type of stainless steel is non-magnetic and highly corrosion resistant, making it ideal for food production & processing & medical applications.

Austenitic stainless steel is typically used to build equipment used in food production.

Examples of austenitic stainless steel include 304 and 316. The former (304) is a type of stainless steel that we typically use in our metal fabrication work, to build our legendary SHOPCraft and MEDICraft ranges of bakery racks, carts, tables and pan dollies.

We use it because it combines good tensile strength with excellent toughness and ductility, it’s highly formable, weldable and machinable, is easy to clean and maintain and performs well under high temperatures.

Ferritic

Magnetic and less corrosion-resistant, but more affordable – this stainless steel type is commonly used in automotive and industrial applications.

Martensitic

Also magnetic, with exceptional strength and hardness properties, martensitic stainless steel is typically used to make cutlery and tools for use in industrial and manufacturing applications.

Martensitic stainless steel is used to make tools like these rods, which are the raw material for a CNC milling machine.

Duplex

This type combines features of austenitic and ferritic stainless steels, offering high strength and resistance to stress corrosion cracking.

Precipitation-Hardening

Very strong and corrosion resistant, this type of stainless steel is commonly used in aerospace manufacturing and chemical processing applications.

Precipitation-hardening stainless steel is typically used to manufacture turbines for aircraft engines.

Stainless Steel Uses And Applications

Choosing the right type of stainless steel for a specific application requires careful consideration of your workplace’s environmental conditions (do you need your stainless steel to be heat resistant, will it be exposed to moisture and chemicals?) mechanical requirements (strength and hardness, ductability, durability and formability/weldability) and cost effectiveness.

Stainless steel grades vary in their composition and properties, so selecting the appropriate one for your business involves balancing all of these factors. Stainless steel’s versatility makes it indispensable in a wide range of industries, including food and beverage, medical and pharmaceutical, chemical, manufacturing, marine and construction.

By selecting the right type and grade, it can meet specific requirements for durability, corrosion resistance, appearance, and functionality in nearly any environment.

If you’d like to learn more about the different types of stainless steel and which would best suit your specific business requirements, please reach out to our expert team.

What’s So Great About Stainless Steel?

At Schaumburg Specialties, we use only the highest quality, American-made stainless steel in our workshop. Stainless steel has many distinct and exceptional advantages that allow us to fabricate some of the best quality production equipment around!

Every time we manufacture a piece of production equipment using stainless steel, we know we’re giving our customers equipment that will perform long term in challenging environments, withstand mechanical stress and wear, is easy to sanitize and maintain and provides tons of aesthetic appeal to help boost branding.

We use stainless steel to make many of our SHOPCraft racks

Versatility

One of the main advantages of stainless steel is its versatility. It comes in so many different types and can perform optimally in so many diverse environments that it would be very tough not to be able to find one to suit your specific application.

Exceptional Corrosion Resistance

Stainless steel is highly resistant to rust and corrosion due to its chromium content, which forms a protective layer of chromium oxide when exposed to air.

It can withstand harsh environments, including moisture, saltwater, and chemicals, making it ideal for marine, chemical, and medical applications.

Durability and Strength

Stainless steel is a strong and tough material that resists wear, deformation, and impact. Certain types such as martensitic stainless steel, are exceptionally hard and suitable for tools and machinery manufacture.

Hygienic and Easy to Clean

Stainless steel’s non-porous surface means it’s easy to clean and sanitize, which makes it ideal for use in commissary kitchens, bakeries and food processing facilities, as well as in hospitals, veterinary surgeries and other medical facilities.

Stainless steel is ideal for food production equipment.

Low Maintenance

Stainless steel requires minimal upkeep because it doesn’t tarnish, pitt or degrade under normal conditions. This reduces lifetime costs, even if your initial investment cost is higher.

Sometimes, we’re asked why our SHOPCraft racks cost a little more than other alternatives – and the answer is because we build them with the highest quality materials that won’t warp or break or let you down, ensuring a sound investment over time and no paying out extortionate amounts of money for repairs and replacements. What’s more, we offer a Lifetime Guarantee on all our equipment, so your initial investment is always safe.

Customizability

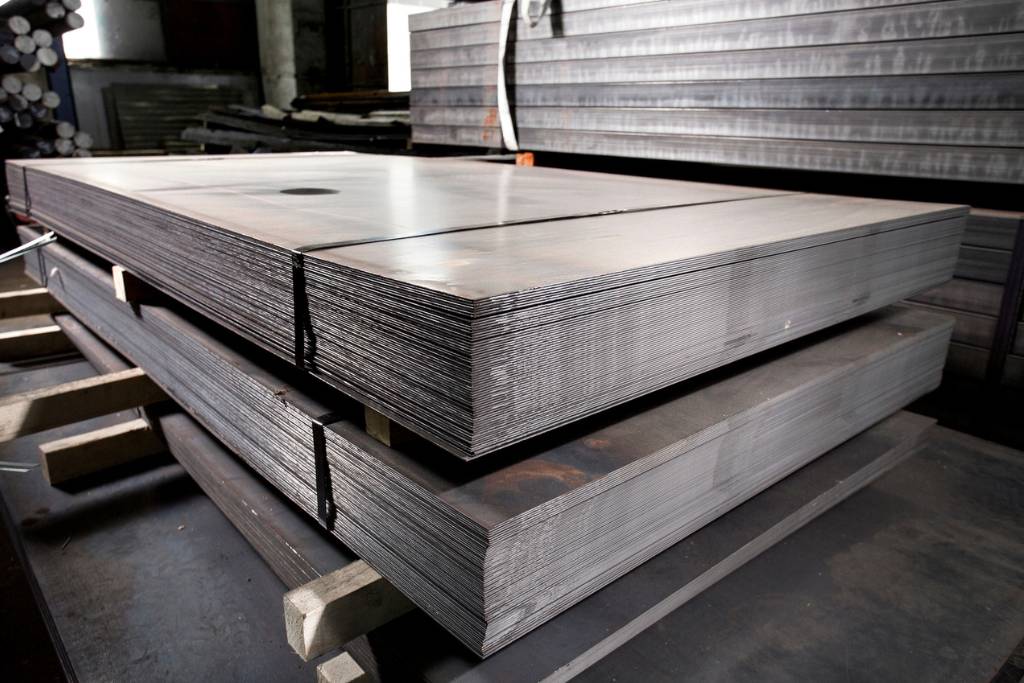

Sheets of stainless steel, ready for use.

The outstanding customizability of stainless steel is another one of its many advantages. It can be manufactured from various forms (sheets, tubes, bars for example) and finishes (polished, brushed, or matte), meeting aesthetic and functional requirements for different uses.

Contact Our Stainless Steel Fabrication Experts

At Schaumburg Specialties, we have been custom building equipment for our valued customers for over 40 years and we value highly the versatility, durability and corrosion resistance of stainless steel that allows us to bring the design visions and unique production equipment requirements of our customers to life.

Contact our expert team today and see what we – and stainless steel! – can do for you!