At Schaumburg Specialties, we have a proud heritage of providing superior equipment solutions to all our clients.

Whether they be in the baking, food processing, manufacturing, pharmaceutical, aerospace or agricultural sectors, we know our busy customers need durable, hyper-efficient product handling systems that help their businesses perform at the very top level, day after day.

Few things are more important to a successful production line than a conveyor system that performs perfectly and consistently, and since the 1980s, Schaumburg Specialties has provided customized conveyor systems for several companies in the Greater Chicago area and beyond.

We take great pride in designing and manufacturing conveyor systems that have transformed our clients’ business efficiency and productivity, while remaining focused on safety and value for money.

In this guide, we tell you all you need to know about conveyor systems and what we at Schaumburg Specialties can do to make your own conveyor design dreams a reality.

The Different Types of Conveyor System

There are many different types of conveyor system out there and all perform different functions, depending on the client’s production needs. Schaumburg Specialties has over forty years’ experience designing and building conveyors in several configurations, including incline, decline, driven, flighted, low/high friction and/or curved.

Conveyor belts are a key component of a conveyor system and we can provide plastic, fabric, wire and roller top belts, as well as flat, friction, or flush grid!

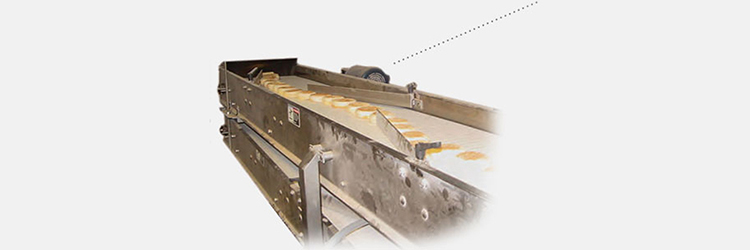

Fabric Conveyor

Fabric conveyors offer one of the most versatile applications out there. The fabric belt can be developed in various elevations, lengths and widths and comes in a flat, troughed slider, v-grooved or roller bed variety.

Modular Plastic Conveyor

Plastic belts are a great way to prolong the useability of your conveyor and ours are constructed with an interlocking pattern for strength and durability. Configurations include straight, incline/decline and radius.

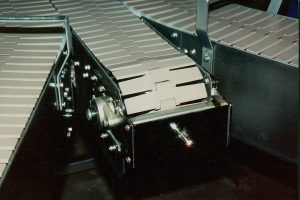

Transfer Unit Conveyors

These play a crucial role in transferring product from one conveyor to the next, retaining fluidity of movement without changing the shape or direction of the product. The units can be installed in existing or new product lines and are super easy to keep clean and sanitized.

These play a crucial role in transferring product from one conveyor to the next, retaining fluidity of movement without changing the shape or direction of the product. The units can be installed in existing or new product lines and are super easy to keep clean and sanitized.

High Speed Single Filer

This conveyor moves product rapidly into a single file, without causing any damage. Schaumburg Specialties engineers can ascertain the safest, most effective speed for your product.

This conveyor moves product rapidly into a single file, without causing any damage. Schaumburg Specialties engineers can ascertain the safest, most effective speed for your product.

Either/Or Vertical Switch conveyor

This conveyor moves products from one level to another via an incline/decline configuration. Choose from a wire rod, plastic or fabric belt for optimal performance.

This conveyor moves products from one level to another via an incline/decline configuration. Choose from a wire rod, plastic or fabric belt for optimal performance.

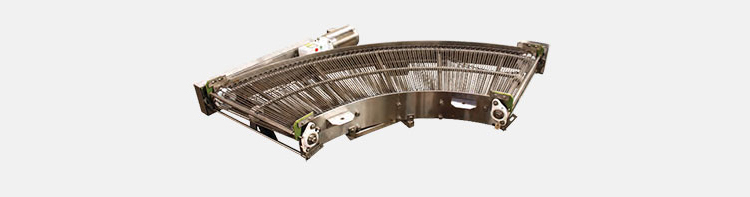

Wire Rod Belt Conveyor

Choose this super smart conveyor in a range of configurations, from straight, radius and tight turning radius. Our team of experts offer a variety of styles and specifications that will match your application exactly.

Choose this super smart conveyor in a range of configurations, from straight, radius and tight turning radius. Our team of experts offer a variety of styles and specifications that will match your application exactly.

Table Top Chain Conveyor

Schaumburg Specialties has applied this conveyor in many industries including food, beverage and pharmaceutical. It comes with a choice of belts and a side-flexing as well as a straight configuration.

Schaumburg Specialties has applied this conveyor in many industries including food, beverage and pharmaceutical. It comes with a choice of belts and a side-flexing as well as a straight configuration.

Unit Machines

These little beauties are the ones that perform the crucial tasks in your conveyor system, making both the quality and quantity of your product consistent, smooth and perfectly formed!

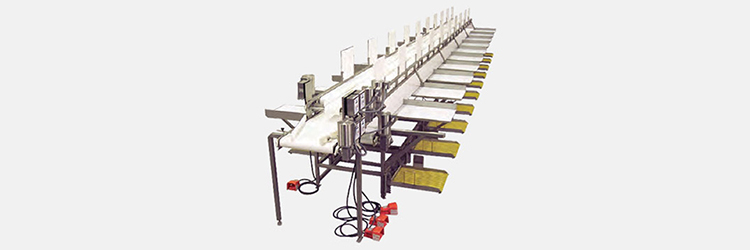

Manual Packaging System

With ergonomically designed packing stations, this system offers the comfort workers need for speedy and efficient production.

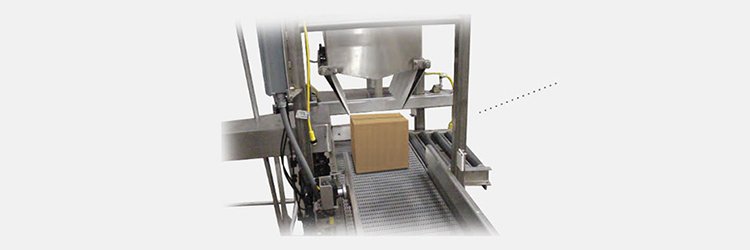

Count and Weigh Auto-Pack System

Single files bulk product, then correctly counts and weighs an item and places it into a carton.

High Speed Auto-Pouch Pack System

Adjusts smoothly to a range of pouch sizes, rates and pack patterns and places products with inch-perfect accuracy.

Other unit machines include: basket stackers, basket un-stackers, basket orientors, basket stack accumulators, basket trash dumps, divert sorters and high speed vertical units, which are specifically constructed for quick, repetitive processes.

Control Systems

Control systems are the heart and soul of any operation and using state-of-the-art technology, we offer smart, graphic driven controls that give you complete automation.

Conveyor Crossover Platforms

When you’re running a highly efficient production line, chances are you have several different conveyor systems in place on a large, busy production floor.

Your workers need free-flowing access to all areas of your production floor and there’s no better way to do this than utilising Conveyor Crossover Platforms. Durable and easy to clean, they allow you and your staff to journey across and between conveyor belts safely and securely.

Schaumburg Specialities

We offer a fully customized service, liaising with our trusted partners where necessary.

- Design – we can work with you to design single solutions or we can design and manufacture the whole production line.

- Management – we can manage the entire process, from concept to reality, including liaising with other vendors to offer a turnkey installation.

- Ongoing support – we will always support our customers when they partner with us, whenever and wherever they need us.

Feel free to discuss your project with us, and we can provide a recommendation! Contact us to speak to one of our experts today.

Get your custom made project up and running with Schaumburg Specialties

Here at Schaumburg Specialties, your productivity is our passion. Regardless of your spatial, budgetary or operational requirements, our team of experts can design and manufacture the conveyor system you need to transform the productivity at the heart of your business. To find out more about how we can help, contact us for a free quote.