What Is Anodized Aluminum?

Aluminum is suitable for cookware because it’s lightweight, conducts heat well and is generally inexpensive – but it’s also naturally reactive with food and is known to have toxic properties.

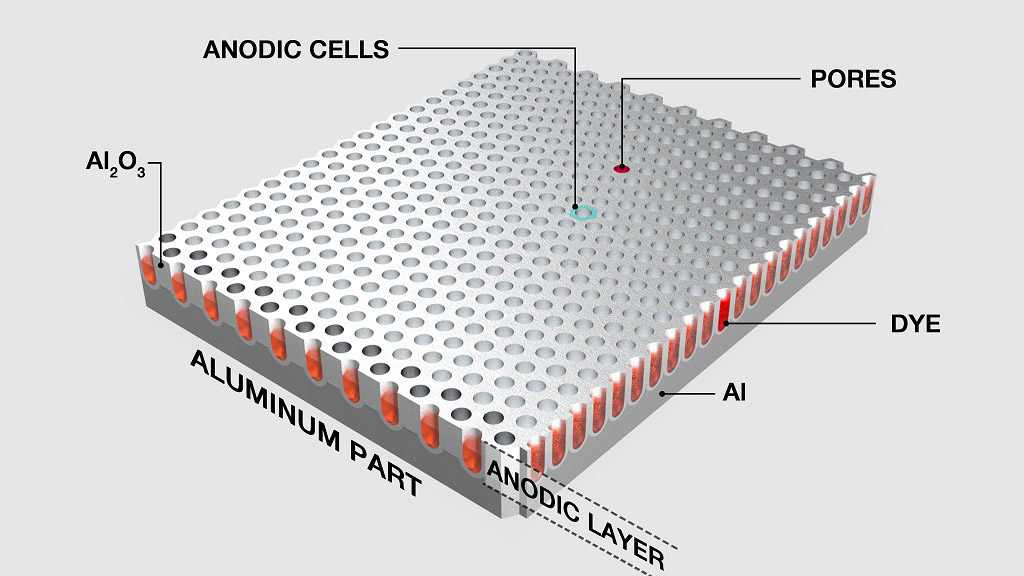

Anodized aluminum is aluminum that has undergone an electrochemical process called anodizing that eliminates these toxic properties and transforms the metal into a non-reactive, food safe, far more durable material. Anodizing thickens the aluminum’s natural oxide layer, forming an anodic oxide finish that is extremely hard, durable, corrosion-resistant and colorable – making it an ideal material for use in industrial and food applications.

How Is Anodizing Done? The Process Explained

Pre-Treatment

Before anodizing can take place, the aluminum needs to be thoroughly cleaned.

Electrolysis

When it’s clean, the aluminum is placed in an acid electrolyte bath (commonly sulfuric acid). An electric current is then passed through it, making the aluminum the anode (hence the name, anodized!).

Barrier Oxide Film Formation

Anodizing causes oxygen ions to bond with aluminum atoms, thickening the natural aluminum oxide layer.

Types Of Aluminum Anodizing Used In The Food Industry

Type 1 – Chromic Acid Anodizing

Chromic acid anodizing uses chromic acid instead of sulfuric acid as the electrolyte. It produces a thin, protective oxide layer on aluminum and is rarely used in aluminum cookware or other food equipment.

Type 2 – Sulphuric Acid Anodizing

Sulphuric acid anodizing uses sulphuric acid as the electrolyte and produces a moderately thick oxide layer on aluminum. It’s the most common type of anodizing for aluminum and is commonly used in consumer-grade cookware because of its durability, colorability and corrosion resistance.

Type 3 – Hard Anodizing

Hard anodizing is an advanced form of anodizing that creates the thickest, most durable anodized aluminum finish. Its extreme durability, wear resistance, and corrosion protection means it’s commonly used in commercial cookware and commercial kitchen equipment applications.

| Type | Name | Thickness | Common Uses | Food Safe? |

|---|---|---|---|---|

| 1 | Chromic Acid Anodizing | Thin | Aerospace, some medical | Rarely |

| 2 | Sulphuric Acid Anodizing | Medium | Consumer Cookware | Yes |

| 3 | Hard Anodizing | Thickest | Commercial Cookware, Food Equipment | Yes |

What About Aluminum Anodizing Colors In Cookware?

How Anodized Colors Are Created

Aluminum anodizing colors are created when the porous oxide later that’s produced during anodizing absorbs dyes or undergoes chemical or electrochemical changes to produce color.

Type 2 anodizing is most common for colored finishes, while Type 3 (hard anodizing) typically results in darker, natural colors such as gray, black and bronze.

Are Colored Anodized Products Food Safe?

Yes, colored anodized aluminum products can be food safe, but the way they’re manufactured and finished is crucial.

- Sealing – the anodized layer must be properly sealed to prevent leaching of dye or aluminum leaching.

- Non-toxic, food-grade dyes – dyes that are specially formulated to meet FDA standards must be used.

- Non-reactive cookware – make sure your colored anodized cookware isn’t coated in any material that could degrade in hot or acidic conditions.

It’s worth noting that colored anodized products are primarily used in the food industry for product differentiation and identification, or to boost aesthetics and branding and not for food contact surfaces.

Some of our color anodized racks

Color-coded racks, for example – such as those manufactured and expertly finished by Schaumburg Specialties – can be instrumental in helping your business remain compliant with the highest food safety standards by separating raw/cooked and allergen/no allergen foods and helping to reduce the risks of cross-contamination.

Popular Colors In Food Industry Use

The most popular colors used in the food industry for non-reactive cookware are black and gray, mainly due to their durability and heat resistant properties.

Red, blue and green are most often used to color-code commercial kitchen equipment and help streamline workflows through enhanced product ID and differentiation. Silver and Clear (uncolored anodized aluminum) is popular for a neutral, professional appearance.

Does Color Affect Performance Or Safety?

As long as your colored anodized cookware and commercial kitchen equipment is properly sealed, and the right dyes are used, there should be no impact on heat conductivity and product performance and no effect on durability or food safety.

However, in low-quality products, poorly sealed dyes may wear off or fade with use. If the anodized layer is scratched or worn off, aluminum leaching may occur, compromising food safety standards.

At Schaumburg Specialties, we’re expert manufacturers of strong, sturdy, properly anodized (and color anodized) food-grade commercial kitchen equipment. To find out more about what we can do for you, inquire today on our website, or call our friendly team at 800 834 8125.

Is Anodized Aluminum Safe For Food Contact?

From the perspective of legislative bodies such as the FDA, anodized aluminum can be food-grade aluminum provided it’s anodized and sealed correctly to meet commercial kitchen equipment and cookware safety standards.

The anodizing process creates a stable, inert and non-toxic layer of aluminum oxide. This hard, corrosion-resistant surface prevents degradation when the metal is cleaned or exposed to high temperatures or acidic foods, while proper sealing of the surface ensures there is no raw aluminum leaching or any residue.

When it comes to dishwasher safety, it’s generally accepted that hard-anodized aluminum cookware is safe to put in a dishwasher, but it’s always advisable to check the manufacturer’s instructions before you do.

Standard anodized or colored anodized aluminum cookware should never go in a dishwasher unless explicitly stated by the manufacturer – this is because of the risk of color fading and corrosion. Unanodized aluminum can never be considered dishwasher safe.

Benefits Of Anodized Aluminum In The Food Industry

The benefits of using anodized aluminum in the food industry are manifold.

- Non-reactive surface for acidic (and alkaline) foods.

- Corrosion resistance – resists moisture and cleaning chemicals, helping prevent aluminum leaching and equipment degradation.

- Durability – highly resistant to heat, wear and tear and scratching, chipping or peeling over time.

- Easy to clean and sanitize in compliance with stringent food safety standards.

- Lightweight, yet strong – a great alternative to stainless steel.

- Color anodizing – helps differentiate products, identify commercial kitchen equipment by function and enhance branding.

Common Applications In Commercial Food Settings

The most common applications for anodized aluminum in commercial food settings are commercial bakeware (including hard-anodized racks and sheet pans), food processing equipment (including prep tables, mixing vats and conveyor chutes) restaurant cookware (pots, sauté pans and skillets) and food transportation and storage containers (including storage racks and carts).

| Application | Anodized Aluminum Product Example |

Key Benefits |

|---|---|---|

| Commercial Bakeware | Chilling & cooling racks; sheet pans; muffin trays; roasting pans; griddles | Durable; conduct heat evenly; heat and corrosion resistant; lightweight; easy to clean. |

| Food Processing Equipment | Food prep tables; conveyor chutes; dough & mixing troughs | Durable; lightweight; non-reactive; corrosion resistant; easy to clean. |

| Restaurant Cookware | Frying and saute pans; pots; skillets | Lightweight; hard-wearing; heat and corrosion-resistant; easy to clean. |

| Food Storage & Transportation | Trays; containers; storage racks & carts | Corrosion & rust-resistant; lightweight; color coded for food safety; easy to clean. |

Hard-Anodized Aluminum Cookware Vs Other Cookware Materials: A Comparison

Hard-Anodized Aluminum Vs Stainless Steel

Hard-anodized aluminum cookware and commercial kitchen equipment versus stainless steel is a common comparison in the food industry. Both are extremely durable, non-reactive and corrosion resistant, however aluminum is far lighter and easier to handle than stainless steel and its heat conductivity is far superior.

Hard-Anodized Aluminum Vs Cast Iron

Both hard-anodized aluminum and cast iron are extremely durable and the heavy conductivity of both is noteworthy – although the heat retention properties of cast iron are excellent compared with anodized aluminum.

Yet, when it comes to weight and usability, anodized aluminum wins hands down. Not only is it lighter and far easier to handle than cast iron, it’s low maintenance (cast iron is difficult to clean) corrosion resistant (cast iron rusts easily) and non-reactive (cast iron reacts with acidic foods).

Hard-Anodized Aluminum Vs Non-Stick Coatings

While hard-anodized aluminum is extremely hard-wearing and durable, non-reactive and food safe, non-stock coatings can be prone to scratching and chipping over time, start to degrade after around 1-3 years and can compromise food safety if scratched or overheated.

Check out the table below for a side-by-side comparison of all the cookware materials and use it to help you decide what’s best for your commercial kitchen needs.

| Feature | Hard–Anodized Aluminum | Stainless Steel | Cast Iron | Non-Stick Coating |

|---|---|---|---|---|

| Heat conductivity | Excellent | Moderate | High | Moderate |

| Reactivity with food | Non-Reactive | Non-Reactive | Reactive (unless seasoned) | Non-Reactive |

| Weight | Light – Medium | Heavy | Very Heavy | Light |

| Maintenance | Moderate | Easy | High | Very Easy |

| Suitable for high heat? | Yes | Yes | Yes | No |

What Are The Downsides Of Anodized Aluminum?

There are many pros of using hard-anodized aluminum cookware and commercial kitchen equipment – but there are also some cons!

This type of cookware is typically more expensive than untreated aluminum and absorbs heat very quickly, so isn’t ideal for items that require high heat. In addition, it’s not fully non-stick so you may need to apply a non-stick coating or use oil when cooking.

Neither is it compatible with induction cooktops (your cooking versatility is limited as a result) and it’s not suitable for metal utensils or abrasive cleaners, as these can scratch the anodized surface and cause leaching or reactions with acidic food, thereby compromising food safety.

How To Check If Your Anodized Cookware Is Food Safe

Our NSF certified commercial kitchen equipment

Look For Manufacturer Certifications

Most anodized aluminum cookware and equipment manufacturers will tell you if it’s food-safe certified. Reputable commercial kitchen brands will almost always list compliance with NSF and FDA food-contact regulations, so look out for their certification labels.

Many of our American-made racks, for example our NSF donut basket racks and Knockdown TX racks are NSF approved too and compliant with FDA hygiene and safety standards – and we will always have the certificate to prove it! We are always happy to custom build and supply NSF-approved racks for our customers. Contact our team today to discuss your requirements and we can make it happen!

Inspect The Surface

A simple inspection of the surface of your anodized cookware can be a big indication if it’s food safe or not. If the cookware has a smooth, dark, matte finish, it’s highly likely it’s been anodized and is safe for food contact. If you spot any flaking, pitting, scratches or dents, discard it, as it’s likely that the surface has been compromised and is not safe for food contact.

When In Doubt, Contact The Manufacturer

If you have any doubts at all about cookware safety standards, contact the manufacturer and request technical specifications, material compliance certificates, confirmation of the type of anodizing that has been done on the product and whether or not it has undergone food safety testing.

Should You Use Anodized Aluminum In Your Food Business?

With its extreme durability, lightweight but strong nature, even heat distribution and non-reactive surface, anodized aluminum cookware and commercial kitchen equipment can be an ideal choice for your food business.

However, you also need to consider some key things before using it for commercial purposes. For example, if you intend to use a product heavily over long periods, then make sure that your anodized aluminum does not have a coating as these can degrade over time. If it does have a coating, ensure it’s NSF certified for commercial use.

Also, be aware that not all anodized equipment is dishwasher safe, so you may lose time having to manually wash your equipment – not ideal for a high-volume, free-flowing commercial kitchen!

And finally, consider your budget. If you can afford to invest upfront for long-term durability and product longevity, then hard-anodized aluminum cookware and equipment is what you need!

Take a look at our table below for a summary of the key points, so you can decide whether anodized aluminum is the smart choice for your food business.

| Consideration | Anodized aluminum is good for you if … | Consider an alternative if … |

|---|---|---|

| Usage Environment | Operate a high volume kitchen/food production facility | Require induction-compatible cookware |

| Food Types | Prepare acidic or high-heat foods | Need non-stick surfaces and don’t use oil |

| Durability Needs | Need long-lasting, corrosion-resistant equipment | Prefer short-term use equipment |

| Maintenance Capacity | Can accommodate light handwashing | Rely on dishwashers for production efficiency |

| Budget Considerations | Can invest upfront | Need low upfront costs |

| Health & Safety Priorities | Want food-safe surfaces | Prefer ceramic/glass surfaces |

Conclusion

Anodized aluminum cookware and food processing equipment is generally safe to use in a commercial kitchen and has many benefits and advantages. However, it also has limitations and these must be considered when deciding whether or not anodized aluminum equipment is a good option for your food business.

At Schaumburg Specialties, we’re always here to guide our customers and provide them with the equipment solution that’s right for them. We have decades of experience in designing, manufacturing and finishing (including anodizing) top-grade, food-safe equipment that lasts a lifetime – guaranteed.

To find out how our friendly, knowledgeable team can help your food business thrive, please contact us via our website or call us at 800 834 8125. We’re always delighted to assist!

FAQ

Is Anodized Aluminum Cookware Safe For Daily Use?

Yes, anodized aluminum cookware is generally safe for daily use. Just be careful not to use harsh chemicals or scourers when cleaning as these can wear the anodized layer down over time. Also avoid using the dishwasher for your cookware unless specified by the manufacturer.

Does Anodized Aluminum Leach Into Food?

No, anodized aluminum shouldn’t leach into food. The anodizing process thickens the natural oxide layer on aluminum, making it hard, non-porous and resistant to corrosion or leaching.

What Is The Healthiest Cookware To Use?

Hard-anodized aluminum, stainless steel, cast iron and ceramic cookware are generally considered the healthiest options. However, all have their pros and cons and you should base your choice of cookware on the type that best serves your specific requirements.

Which Is Better? Anodized Aluminum Or Stainless Steel?

Both are extremely durable, non-reactive, corrosion resistant and easy to clean and maintain. However aluminum is far lighter and easier to handle than stainless steel and its heat conductivity is far superior.

Can Anodized Cookware Be Recycled?

Yes, anodized aluminum can be recycled because aluminum is a highly recyclable material and the anodized layer is a surface treatment, so it won’t affect recycling. However, the cookware must be 100% metal (no plastic, rubber handles or non-stick coatings) and it’s advisable to check with your local recycling center for instructions on the best way to dispose of your anodized aluminum pan or other equipment.

Conclusion

Hard-anodized aluminum is widely used for cooking-related purposes and has a host of benefits to consider. If you want to learn more about this material or you’re in need of other custom metal fabrication, don’t hesitate to reach out to us at Schaumburg Specialties for more information!