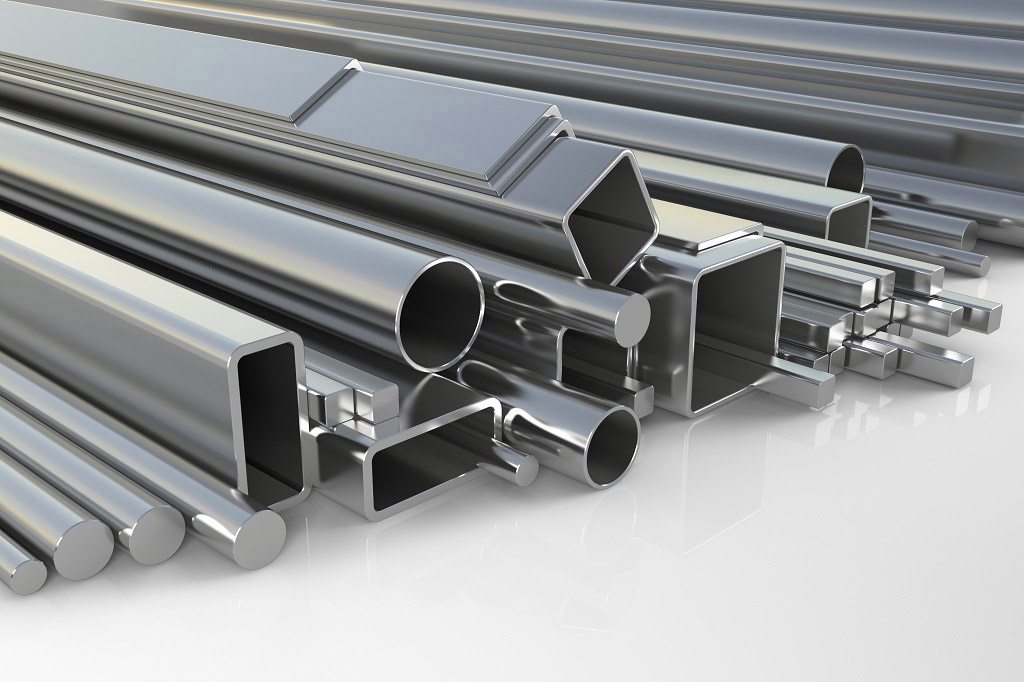

Aluminum is an indispensable engineering material present in all facets of modern life. From pots and pans to aircraft, motor vehicles, and smartphones, its versatile nature offers many practical applications that extend from domestic use to outer space. Its lightweight, highly malleable, and recyclable characteristics make it a desirable manufacturing material in an increasingly environmentally conscious world.

When it comes to aluminum vs. steel strength, the former can be forged, with the right alloy and processing technique, to be just as durable as steel. Considering this silvery-white metal is one-third the weight of the latter and corrosion-resistant, it offers numerous benefits for metal fabricators and their product consumers.

How Is The Strength of Aluminum Measured?

The durability of metal, including aluminum, is determined by four mechanical properties: compressive, tensile, yield, and impact strength.

- Compressive strength: The ability to withstand heavy loads pushing down.

- Tensile strength: How much tension a metal can withstand before pulling apart.

- Yield strength: The capacity to withstand being reshaped or bent from a load (when a metal’s yield point is surpassed, it will bend.)

- Impact strength: Determined by a Lzod or Charpy impact test, this determines if a metal can withstand a sudden load and the amount of impact required to fracture it.

The mechanical strength of aluminum can be increased through cold working and alloying. Regardless of its alloy, it doesn’t become brittle at low temperatures and retains ductility.

Why Is Aluminum Strong?

Aluminum is one of the most malleable metals. Its strength increases exponentially when alloyed with other metals like magnesium, copper, and zinc. Zinc, in particular, produces heat-treatable aluminum alloys that permit precipitation hardening, producing aluminum of the highest durability.

Aluminum alloys can be modified through various combinations of cold working, alloying, and heat-treating processes. These processes are designed to keep atoms in place, inhibiting their movement and strengthening the finished product.

Just how strong is aluminum? Well, the strongest alloys can attain strengths of 72,000 pounds per square inch and are often used in aeronautical applications. Aluminum’s unique strength can be attributed to its chemical compounds, making it three times lighter than iron and stronger than steel when alloyed.

Where Is Aluminum Used?

Aluminum is a trusted metal among scientists, manufacturers, and engineers. Due to its incredible ability to perform in extreme conditions, it is used for many industrial applications from construction to transport to food processing and packaging.

- The military: This durable metal is utilized in heavy-duty military vehicles, body armor, and weapons because it can endure harsh conditions.

- NASA: Aluminum is used to protect satellites, telescopes, and rockets from the vacuum of space, as well as in metal reflectors to combat radiation.

- The air force: Because it’s lightweight and saves fuel, it’s the primary metal used to manufacture aircraft shells and seats.

- Construction: Aluminum is commonly found within; external facades, roofs, walls, windows and doors, staircases, railings, and shelves.

- Food and Beverages: Some soda can alloys contain aluminum. Commercial kitchen equipment frequently contains aluminum too.

Aluminum Strength vs. Steel

The many steel and aluminum alloys vary in strength, so it’s difficult to answer which metal is outright stronger than the other. On its own, steel is stronger because it contains large amounts of carbon, but it is also incredibly dense and heavy. So, when it comes to the strength-to-weight ratio, aluminum triumphs.

Strength is also about durability and the ability to withstand pressure, weather, and damage. Due to a thin layer of oxide that forms on its surface, aluminum has natural corrosion resistance. Its malleability allows bending without cracking, while its ductility enables stretching without breaking. Aluminum also performs well in cold weather and becomes stronger as the temperature falls.

Circumstantially, aluminum may be adversely affected in marine environments if it is exposed to chloride, which causes galvanic corrosion. However, from weight advantages and corrosion resistance to versatility as an extruded product, aluminum is an obvious choice for industrial and commercial industrial applications.

Aluminum Lifespan

So, is aluminum sustainable? According to the Aluminum Association, 75% of all aluminum ever produced is still in use. The metal’s long lifecycle is favorable to today’s climate where recycling, being eco-friendly, and energy-efficient are major concerns for future generations.

As a metal, aluminum sustainability is remarkable. It has a lifespan that few other metals can match. It is recyclable without degradation, and its secondary production consumes 95% less energy than the first.

Conclusion

The many applications of aluminum are a testament to its durability. At Schaumburg Specialties, we have a range of custom aluminum racks and carts specially manufactured to suit a range of industries. Our expert metal fabricators can also engineer and design products from scratch. Have something you need to be made? Contact us here to find out how we can help.