You may not be able to tell a huge difference between aluminum and stainless steel to the naked eye. Both metals are extremely versatile and widely used in the food services industry.

However, when it comes to factors such as application, sturdiness, weight, cost, and more, many noteworthy differences will impact which material you choose.

We’ve broken down the differences between aluminum and stainless steel to give you an idea of which is better for your particular project.

What Is Aluminum?

Aluminum is a lightweight metal while still offering a high level of strength, especially when it’s blended with alloy elements. It has a high oxidation level, and when it becomes oxidized, its surface will turn white. Aluminum is one of the most widely used nonferrous metals on the planet.

What Is Stainless Steel?

Stainless steel is made from a group of iron-based alloys made from roughly 11 percent chromium. Its composition prevents stainless steel from rusting and gives stainless steel its heat-resistant properties. It is widely used in kitchen accessories such as cookware and cutlery. It can also be used to make grills, sinks, saucepans, and more.

Weight

Generally, aluminum is one-third the weight of stainless steel, alluding to why it is so widely used in airplane or bicycle manufacturing. On the other hand, stainless steel is extremely strong and is less likely to bend, warp, or become deformed under both force and heat.

The tradeoff for stainless steel’s impressive strength is how dense and heavy it is. Stainless steel is usually about 2.5 times denser than aluminum.

Strength-to-Weight Ratio

As we mentioned above, aluminum weighs only one-third of the weight of stainless steel. Its lightweight yet durable nature makes it ideal for manufacturing large pieces of equipment that still need to be aerodynamic.

Stainless steel is on the opposite end of the spectrum in terms of its strength-to-weight ratio. It is extremely dense, making it heavy and difficult to use in industries that require a ton of movement.

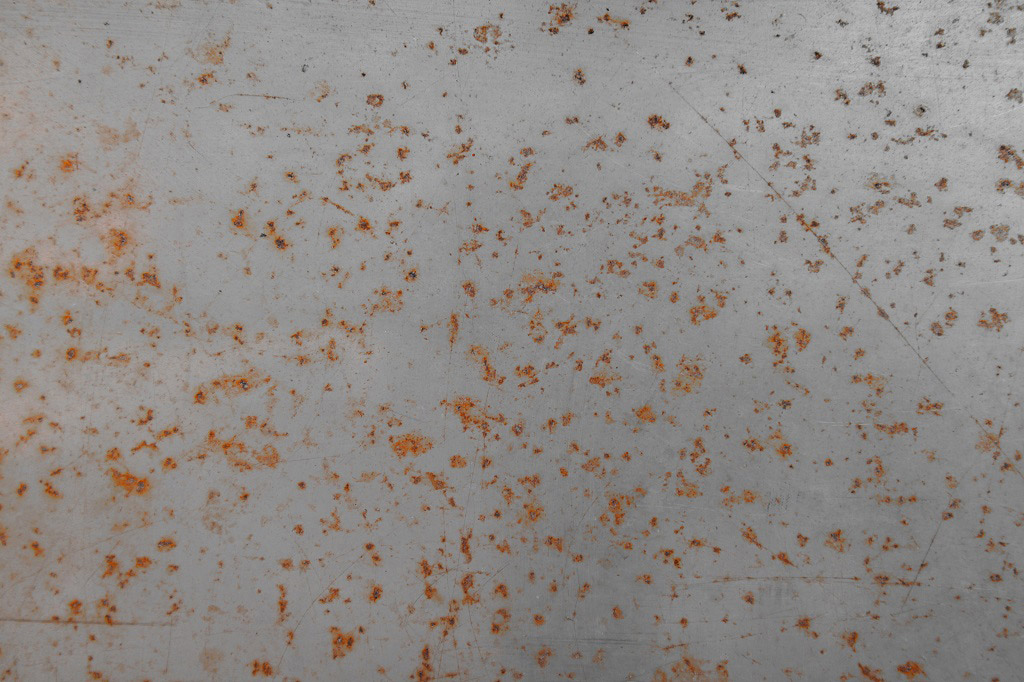

Aluminum vs. Stainless Steel Corrosion Resistance

Aluminum vs. stainless steel corrosion is another factor to consider. Both aluminum and stainless steel are used around liquids, they must be resistant to corrosion. Rust is a particular type of corrosion that occurs when metal wears away over time.

One of aluminum’s greatest upsides is the fact that it’s corrosion-resistant. It doesn’t require any additional treatment after it is produced, and it doesn’t ever develop a layer of rust. Pure aluminum doesn’t require any sort of paint or protective coating that scratches off and requires recoating.

In many environments, aluminum is known for its corrosion resistance. As long as aluminum contains a very thin layer of oxide, it is extremely corrosion-resistant. This layer is only ~5 nanometers thick and acts as a passive layer on the outside of the steel. Stainless steel, on the other hand, is corrosion resistant all the way through, and it contains nickel, an alloying element that helps stainless steels resist corrosion.

Cost

The sheer cost of each material impacts what products are produced with each. The global supply of both stainless steel and aluminum directly impacts the market price for both aluminum and stainless steel. Supply and demand, in addition to the fuel costs, also factor into the price. Directly comparing the cost of stainless steel and aluminum, aluminum is typically cheaper than stainless steel.

Conductivity

Aluminum and stainless steel are opposites when it comes to conductivity. Pure aluminum has an electrical conductivity at room temperature of ~38 million siemens per meter. Pure aluminum’s thermal conductivity is 235 watts per kelvin per meter. For example, heat sinks are often made from aluminum due to their good thermal conductivity.

Aluminum alloys have a lower electrical and thermal conductivity, however, stainless steel has a thermal conductivity of ~15 watts per kelvin meter and electrical conductivity of ~1.4 million siemens per meter.

As you can see by the numbers above, aluminum conducts electricity significantly better than stainless steel. Stainless steel is one of the worst conductors of electricity across all metals.

Welding

Welding is essential in transforming both aluminum and stainless steel into usable parts, such as bakery racks and medical equipment. The type of aluminum that you are trying to weld will impact how well the material welds.

Comparing aluminum and stainless steel, aluminum is more difficult to weld. However, all aluminum alloys are readily welded.

Although stainless steel is generally easier to weld, it requires care because of its low thermal conductivity. Excessive heat buildup may result in discoloration, warping. When done professionally, stainless steel can produce strong and lasting welds.

Malleability

How malleable aluminum is, depends on its composition, as 5052 aluminum is highly malleable while 6061 aluminum has a higher chance of cracking. Although stainless steel can be configured into different shapes, it is not as easy to do compared to aluminum.

Conclusion

Which is better, aluminum or stainless steel? The answer to this question depends on the product being made in addition to the situations in which each product will be used. Aluminum products are lightweight, durable, and weather-resistant.

Stainless steel products have superior strength and corrosion resistance compared to aluminum. Aluminum, on the other hand, is a lighter metal that will not rust. If you’re not sure which metal to use for your metal fabrication needs, reach out to our experts at Schaumburg Specialties today.

We can provide you with hands-on guidance to ensure the products you need for your business are built to last a lifetime. Call us today at 855-929-1129 to get started!