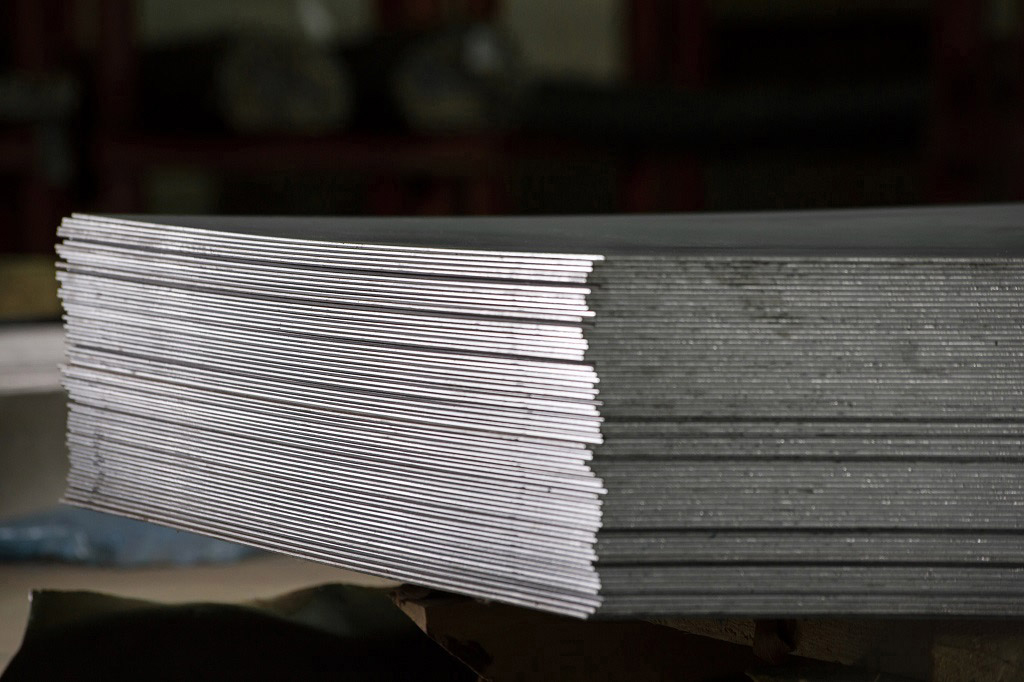

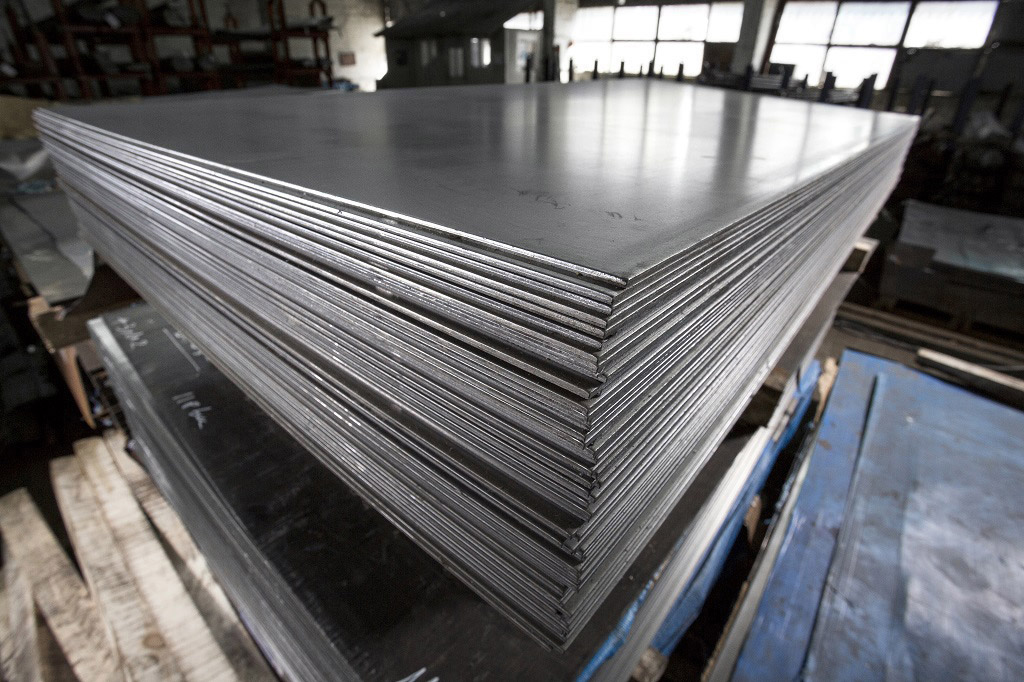

Stainless steel is an incredibly versatile material. With four main formulations of stainless steel, each comes with unique properties in terms of resistance to corrosion and oxidation, tensile strength, and melting point.

To ensure you choose the right type of stainless steel for your needs, it’s important to understand the properties of each and the ideal applications. Let’s delve into the different types of stainless steel below.

Austenitic Stainless Steel

Austenitic is the most common type of stainless steel. This type of stainless steel has a high nickel content in addition to high amounts of chromium, molybdenum, and nitrogen when compared with the three other different stainless steel types.

Not only is austenitic stainless steel incredibly malleable, but it is renowned for its weldability in metal applications. This type of stainless steel is used in high-strength applications and is commonly utilized in storage components and kitchen cutlery.

Because this form of stainless steel is highly resistant to corrosion, it is commonly used where corrosion is present. Alloys 304 and 904L are common.

The one downside of austenitic stainless steel is how pricey it can be.

Grade 301 Stainless Steel

This is an example of austenitic stainless steel that is highly ductile and has high weldability. It is ideal for creating formed products, and it will harden quickly during mechanical working.

Grade 302 Stainless Steel

This alloy contains similar amounts of nickel and chromium to grade 304 stainless steel (the most common type), and it is typically sold in the form of a strip or wire. It is known to be used in conical compression springs.

Grade 303 Stainless Steel

Grade 303 stainless steel is used when the production process consists of extensive machining in automatic screw machines. The addition of sulfur lowers the corrosion resistance compared to grade 304 stainless steel.

Grade 309 Stainless Steel

Another example of austenitic chromium-nickel stainless steel, grade 309 is utilized in parts that must be resistant to corrosion, heat, and oxidation up to 2000 degrees Fahrenheit.

Grade 316 Stainless Steel

This type has high tensile strength and has better resistance to chlorides compared with grade 304 stainless steel. It is ideal to use when the exposure to salt (or other chlorides) will be high.

Grade 321 Stainless Steel

This is a stabilized austenitic stainless steel that contains titanium and carbon. The addition of titanium prevents precipitation from occurring during the welding process.

Ferritic Stainless Steel

This type of stainless steel contains low amounts of carbon (less than .10 percent). Other minerals may also be added to steel, the main component is chromium. Ferritic stainless steel is also known to contain nickel.

The magnetic properties in ferritic stainless steel make them highly resistant to cracking due to stress corrosion. This property makes ferritic stainless steel particularly useful in products that have the potential to come into contact with potentially corrosive materials such as kitchen cookware, car components, and industrial entities.

The most common varieties of stainless steel include alloys 430 and 434.

Grade 409 Stainless Steel

This variety of stainless steel is used for general purposes, containing roughly 11 percent chromium. Grade 409 is utilized in scenarios that require oxidation or corrosion protection when carbon steel and other coated steel cannot.

Grade 430 Stainless Steel

This type of stainless steel is known for its resistance against nitric acid. Despite it having a lower-than-average tensile rate, It is incredibly strong and used in a range of intense applications.

Grade 434 Stainless Steel

This is a stronger alternative compared with grade 430 stainless steel. It has high tensile strength and maximum operating temperature, giving it a slight edge in high-temperature scenarios compared with grade 430 stainless steel.

Grade 440 Stainless Steel

Grade 440 is high-carbon steel known for its hardness and wear resistance. It is commonly utilized in knives because it offers strength and corrosion resistance at an affordable price point.

Martensitic Stainless Steel

The third stainless steel type is martensitic stainless steel. These steels contain a similar structure to ferritic stainless steels with a varying amount of carbon. The amount of carbon in ferritic stainless steel is under 0.20%, while martensitic stainless steels have a carbon content between 0.61% and 1.50%.

While the carbon difference may not seem significant, it allows martensitic stainless steels to be hardened, making them ideal to use in high-strength, average corrosion situations. For example, valves or pumps are often made from martensitic stainless steel, but the applications extend far beyond these examples.

Grade 410 Stainless Steel

This type of stainless steel is known for its high strength, corrosion resistance, and hardness. In both the hardened and annealed conditions, grade 410 stainless steel is magnetic. Utilizing different heat treatments, many properties can be developed.

Grade 420 Stainless Steel

Grade 420 stainless steel doesn’t have the same chemical resistance as other austenitic and ferritic stainless steels, but it is known to be resistant to acids, water, food compounds, and some alkalis. It is a go-to choice in scenarios that require high tensile strength and impact resistance.

Grade 630 Stainless Steel

This stainless steel variety is magnetic in both its precipitation hardened condition and in the solution annealed condition. It is known for its strength and hardness.

Duplex Stainless Steel

Duplex stainless steels combine the properties of ferritic and austenitic stainless steels. While they are stronger than these varieties, they don’t have as much nickel, making them more affordable.

This type of stainless steel is often used in the underwater oil industry due to its high corrosion resistance. The extended exposure to saltwater does not impact duplex stainless steel.

It is malleable and weldable, often made into different shapes and components.

Conclusion

If you need assistance choosing the best stainless steel quality type for your needs, our team at Schaumburg Specialties is happy to assist you. Although we are not metallurgists or specialize in stainless steel specification we can help in directing you to persons that are knowledgeable in this area. Don’t hesitate to give us a call at 855-216-1284 to learn more about how we can help.