At Schaumburg Specialties, metal fabrication is in our DNA and has been for over 40 years. We use the highest quality materials to produce premium quality production equipment that lasts a lifetime – and that’s a fact!

How can we be so sure of the superior quality of our equipment? Because of the techniques used by our highly skilled welders and the top notch aluminum and stainless steel we use to manufacture it.

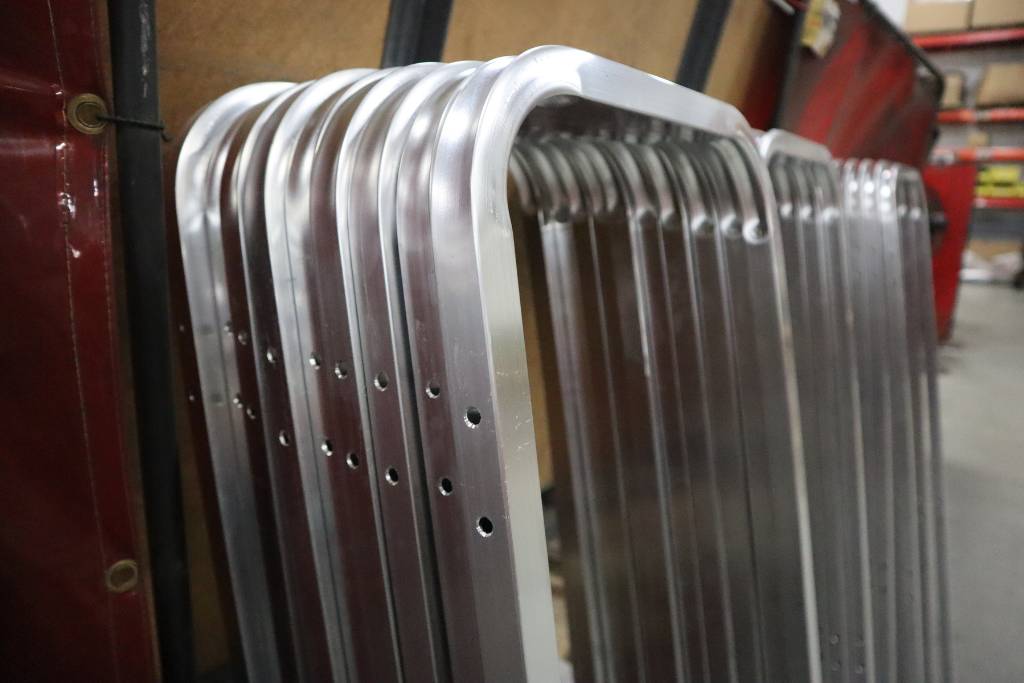

Whatever your application or industry – be it food, baking, manufacturing, medical or indoor farming – our iconic SHOPCraft, INTELLICraft, MEDICraft and AGRICraft ranges provide you with double all welded production equipment made from top grade materials that can transform the efficiency and productivity of your business.

In fact, we’re so sure of the premium quality materials and craftsmanship used in our products that we offer a Lifetime Guarantee on every piece we produce. We will repair or replace any defective equipment covered by this warranty, provided the damage isn’t due to wear and tear and the product has been used for its intended purpose.

Read on to discover exactly why the welding process and the materials we use in the fabrication of our metal equipment matters so much and why they’re so key to the quality of our products.

Why Welding Matters

Welding is a crucial part of manufacturing metal equipment. The process (and how well it’s executed!) matters because it dictates how your equipment performs, how structurally sound it is, whether it’s safe and reliable to use and how long it lasts.

At Schaumburg Specialties, our highly trained, skilled and dedicated team employs a variety of advanced welding techniques to manufacture products that are guaranteed to perform and stand the test of time and heavy use.

Our welders use advanced techniques

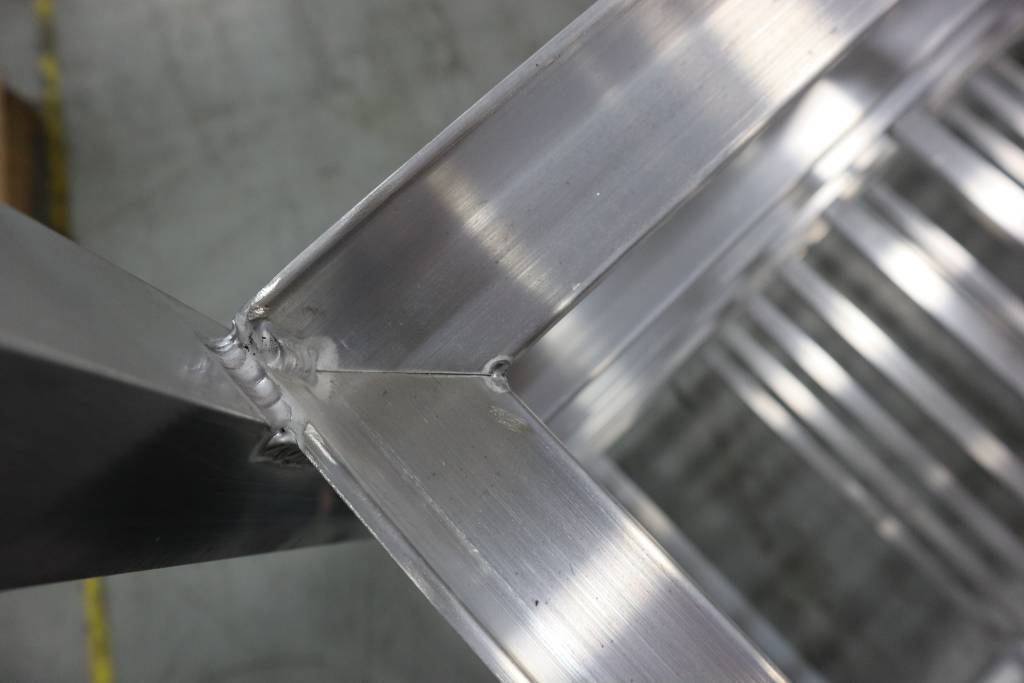

All of our custom built equipment is double welded as standard and this is something that sets us apart from our competitors.

Many companies will complete one straight weld straight down the side of a bakery rack for example. Our team will always double weld along the top of and down the front of each tube, thereby ensuring the strength, structural integrity, safety and durability of all our racks and other custom build equipment.

Our equipment is all double welded

We also weld a reinforcing X brace (or a Z brace for nesting racks) as standard on all our racks. This helps to ensure their strength, durability and lifespan and means you’re highly unlikely to ever see any breaking, tipping or swaying occurring – or any dropping and waste of your product. Having oven racks that are robustly welded and structurally sound also helps ensure that your workplace is compliant with the very highest health and safety regulations for employees.

Welded X brace and Z brace reinforcements

The all double welded construction of our SHOPCraft racks also helps keep bakery sheet pan racks and other kitchen equipment clean and sanitary. Each tube end is welded closed, leaving no space in which bacteria and germs can thrive, and helping your business keep compliant with the strictest food hygiene standards.

Welding is also essential for the precision engineering of all our custom build equipment. We can solve any production challenge for our customers and these challenges are often quite specific to a particular business. The welding expertise of our team allows us to precisely join parts together, exactly how and where our customers need them, to create equipment that meets our client’s unique requirements.

Now we know why welding is so instrumental in the crafting of our top notch equipment, continue reading to discover why the materials we use are crucial too.

Why Materials Matter

At Schaumburg Specialties, every single one of our products is made from premium quality American aluminum or stainless steel, which makes it better performing, stronger, more durable and more reliable than often-imported competitor alternatives.

We use only top quality materials

This use of quality materials means that every piece of equipment we produce is top quality too – strong, sturdy and built to last. It also means it’s highly corrosion and rust resistant, which is crucial for applications in industrial kitchens or in marine and chemical manufacturing environments where conditions can be harsh and extreme and metals are exposed to abrasive or corrosive substances.

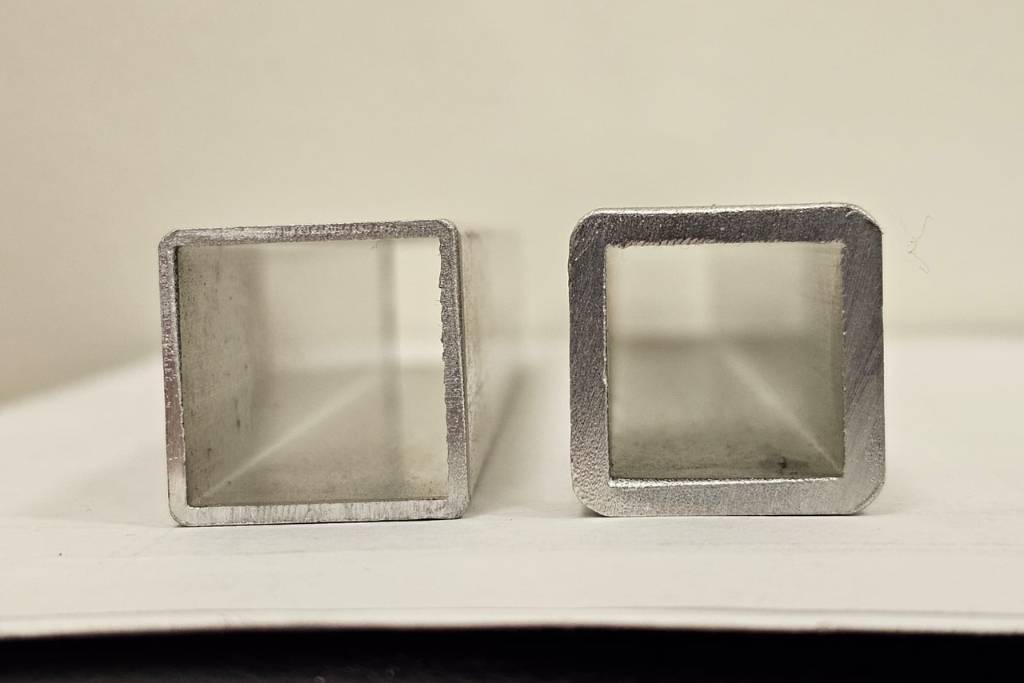

Not only does the quality of the materials matter, the thickness of those materials matters too! The thickness of the metal used can often determine how well a piece of equipment will perform and its suitability for use in a specific application. It dictates the reliability of your production equipment and whether it can provide efficiency, productivity and profitability for your business.

At Schaumburg Specialties, we typically find that using thicker aluminum or stainless steel means better quality, more durable and longer lasting production equipment for our clients.

In a commercial bakery, for example, one of our SHOPCraft racks, which is made of thicker metal than its nearest competitor – and can weigh double! – would perform reliably and consistently even in extremely high oven temperatures or icy freezer or cooling conditions.

We use notably thicker metal than our competitors

Using premium quality, thicker materials means your equipment will be more durable and able to consistently and reliably withstand harsh environments and corrosion over time. Such reliably strong and sturdy equipment ensures that our custom built pieces will last a lifetime and you won’t have to worry about paying out for expensive repairs and replacements further down the line.

Our premium quality SHOPCraft, MEDICraft and INTELLICraft production equipment will undoubtedly cost a little more than our competitors in the short term. Yet, this is because we’re using thicker, better quality materials, so you’re always getting more and much better value for your money.

Trust Schaumburg Specialties For Premium Quality Products & Value For Money

Here at Schaumburg Specialties, your productivity is our passion. That’s why we only provide double all welded production equipment crafted from premium quality American materials that’s guaranteed to last a lifetime.

Regardless of your budgetary or operational requirements, our team will work with you to find the expertly designed and fabricated custom build or customization solution that will enhance the efficiency and productivity of your business. To find out more about how we can help, contact us for a free quote.