Machineries in the food industry need to be lubricated to ensure the smoothness in production and to reduce wear, corrosion, friction and oxidation. However, leakages can’t be avoided and lubricants won’t discriminate when it comes to the material it comes in contact with. This is why it is important for food manufacturers to choose the right lubricant for the job in order to ensure the safety of the consumers.

This is where

food grade grease comes in.

Food grade grease functions like any other machinery lubricant which is to protect the equipment against corrosion, friction and oxidation. Additionally, it needs to resist degradation from water and chemicals and must not react towards elastomers and plastics.

Food grade grease has been around since the 1960’s and they continue to be an integral part of the food and beverage industry up to this day.

What Is Food Grade Grease Made Of?

Food grade grease is divided into two classes: non-synthetic and synthetic. The difference between the two is mostly in the raw material they are based in.

Non-synthetic lubricants are mineral oil based. However, the term “mineral oil” includes a wide range of products including crude oil and white mineral oil which is derived from petroleum. These oils are highly refined and are odorless, tasteless, colorless, non-staining and must meet the regulations specified in

Title 21 CFR 178.3620.

Synthetic lubricants are based on chemicals other than crude oil which are most often esters or olefins. When compared to mineral oils, they have a greater oxidation stability and are commonly used in high temperature applications.

Is Food Grade Grease Safe?

Both non-synthetic and synthetic lubricants need to be classified as “food grade” before it can be used in food and beverage manufacturing plants. Being classified as a food-grade lubricant means that the grease is not toxic when consumed and it doesn’t have toxic additives like lead, lithium and zinc.

Lubricants that have been officially classified as “food grade” are safe for consumption in trace amounts which means that the average concentration is less than 100 micrograms per gram.

Categories of Food-Grade

The United States Department of Agriculture (USDA) is the agency responsible for consumer safety issues regarding the food-processing industry. Initially, they only covered federally inspected meat and poultry facilities but their scope rapidly grew to other sectors such as fisheries and retail food operations. They are also the agency responsible for the registration of food grade lubricants and created the categories of food grade grease. These food-grade designations are classified based on the risk of contact with food.

However, the USDA has no longer been reviewing federally inspecting food process facilities since September 30, 1998 and the National Sanitation Foundation or NSF has taken over the responsibilities of the USDA with regards to the food-processing industry.

The NSF International is a non-profit and independent organization that develops health standards and certification programs that help protect the world’s food. It was founded in 1944 as the National Sanitation Foundation but the organization changed its name NSF International in 1990 as they expanded their services beyond sanitation and into global markets. They are responsible for updating and upgrading the categories of food-grade lubricants created by the USDA to how we know them today.

- H1 – This is the category of food grade grease used in food processing which involves possible incidental food contact. These are not intended to come in contact with food but are to be used in instances where contact may occur. Lubricant formulations may only be composed of approved basestocks, additives and thickeners listed in Title 21 CFR 178.3750.

- H2 – This is the category of food grade grease used in food processing which involves no possibility of incidental food contact. Unlike H1, H2 lubricants don’t have a list of acceptable ingredients because they won’t come in contact with food. However, they can’t intentionally contain heavy metals such as antimony, arsenic, cadmium, lead, mercury or selenium and must not include substances that are carcinogens, mutagens, teratogens or mineral acids.

- H3 – This is the category of food grade grease used in food processing which is used to prevent rust on hooks, trolleys and other metallic equipment where direct food contact would occur. The products may be composed of the following:

- Edible oils (corn oil, cottonseed oil, soybean oil) complying with 21 CFR, Section 172.860;

- Mineral oil complying with 21 CFR, Section 172.878;

- GRAS substances complying with 21 CFR, Parts 182 or 184

- 3H – This is the category of food grade grease used in food manufacturing used to protect seals, bearings, blades, grills, ovens, loaf pans, boning benches, chopping boards and other hard surfaces to prevent food from adhering during processing.

- HT1 – This is the category of lubricants that is used to heat transfer fluids in heating and cooling systems in food manufacturing facilities.

- P1 – This is the category of food grade grease used in accordance with the conditions set forth in the United States Department of Agriculture’s letter of acceptance.

All of the aforementioned categories are considered to be “food grade”. However, it is important to keep in mind that only lubricants registered as H1 are truly food grade.

To further ensure the safety of the products, a lubrication safety audit should be performed every three years. This audit will not only guarantee the safety of the food or beverage being manufactured but it will also secure the optimal performance of the machinery thus lowering the cost of maintenance and lowering the chances of misapplication of the lubricants.

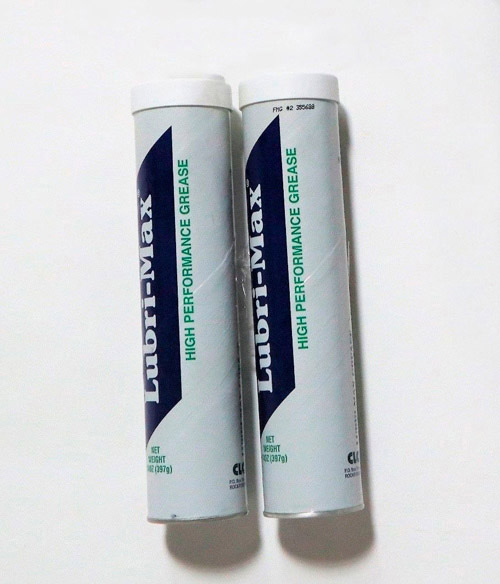

Best Food Grade Grease

In recent years, the demand for processed food has increased and consequently, the food-grade grease market has experienced an exponential growth. Between 2015 and 2020, the industry’s compound growth rate of 6.7% and the market estimate is projected to reach 256.5 million dollars by 2021.

Such growth has brought a considerable amount of food products to the public and if you happen to be looking for a good food grade grease, then chances are, you will have a hard time. There are a lot of options and the whole ordeal can be overwhelming for someone who is new to the industry.

An effective food grade grease must be able to balance quality, efficiency, and safety. Here are some considerations:

Operating Temperature

The first thing to consider is the operating temperature of the food making process.

When buying food grade grease, you will have to choose whether you will use the non-synthetic (mineral oil based) or the synthetic kind. Mineral oil-based grease should only be used in hydraulic systems that operate at temperatures between 120°F to 150°F since it will oxidize and create carbon deposits in the equipment if used in temperatures above that range.

On the other hand, synthetic

food grade grease can function both in high and low temperatures. The temperature range of most synthetic lubricants in the market today is between -50°F to 325°F. There are even food grade greases available with a dropping point (the temperature at which it becomes liquid) of 514°F. In addition, synthetic food grade lubricants also provide more hydrolytic stability and a higher viscosity index keeping your equipment running smoothly for a longer period of time.

Base Oil Viscosity

The viscosity is the base oil is another important consideration when choosing the right food grade grease. It should be appropriate for the load and speed of the application at operating temperature.

Greases with higher viscosity are more water resistant and are suited to heavy-duty applications. On the other hand, greases with a lower viscosity are suited for slow speed and heavily loaded operations.

Viscosity is the key factor in wear protection and efficiency. Thus, you should consider your options carefully by evaluating your operations first.

Application and Re-application

Over-greasing and under-greasing is the cause for many equipment failures in the food making industry. With that being said, proper application is important to avoid any costly repairs and using a grease gun will help you achieve a

proper and even grease application. Additionally, you should thoroughly clean the previous grease from your equipment before re-applying in order for the food grade grease to perform at an optimum level.

Choosing the right food grade grease is an important aspect in the efficiency and operation of your food business. If you are looking for the best food grade grease in Illinois then check us out at

Schaumburg Specialties or give us a call at 800-834-8125. We are more than happy to assist you.