Metal coating, just as it sounds, is the process of applying some type of outer metal coating to the surface of a product or other component. Metal coatings provide a host of advantages, such as improving performance or appearance.

As you can imagine, the number of material options is endless, with each offering unique benefits and disadvantages across industries. Some coatings are designed with a functional purpose, such as reducing friction between two metal components. This application is especially utilized in the construction and manufacturing industries.

Other metal coatings may be applied to create a more uniform look across multiple parts or to improve the aesthetics of a metal part. If you’re interested in exploring metal coating and how it can improve certain aspects of your business, we’ve compiled a helpful guide below.

What Is Metal Coating?

To keep metal products and materials in as good shape as possible, they are oftentimes covered in metal coatings. Without this coating, the environment will undoubtedly have an impact on the metal, causing it to corrode and rust.

Common examples of metal coating materials include polymers such as epoxy, moisture-cure urethane, and polyurethane. The type of coating depends on what the product will ultimately be used for, as different coatings offer different levels of protection.

For example, some coatings are applied to protect the under metal from dirt, debris, rust, or corrosion. These types of metal coatings are typically used for outdoor products such as outdoor patio sets or pool accessories. The coatings protect from potentially damaging weather taking a toll on your furniture.

On a larger scale, metal coatings also help protect heavy-duty equipment such as trains, cars, boats, and airplanes. As these products are manufactured, they’re exposed to agents such as lubricants, oil, fuel, or dirt that can all cause damage and detract from the quality. This is where metal coatings come into play, as they help the product withstand any potential damage.

Specifically, they prevent the chipping or scratching of the surface beneath the metal coating, as many of these large-scale pieces of equipment inflict at least some amount of damage during operation. The coatings themselves are flexible and move with the product they’re covering to help further resist damage.

In other applications and industries, metal coatings can also act as torque agents or lubricants. Think of parts such as fasteners, screws, and bolts that are constantly tightened or unscrewed. The metal coating can protect the structure from becoming damaged or worn-down.

Look around your home and chances are high that you can find something that has a metal coating. Galvanized steel is an especially popular example of metal coating that’s used in a variety of ways including benches, bolts, nails, staircases, ladders, and more.

Metal finishings come in a range of finishes to meet the aesthetic needs of the application. For example, airplanes or cars need to have smooth metal finishes to ensure the vehicle can travel as it normally would. Manufacturers of these vehicles choose the color of the metal coating to best match the product as a whole, oftentimes choosing the most subtle color possible.

Metal coatings come in two different forms, both liquid, and powder. The product itself can be sprayed with the coating, or it can be dipped into a metal coating.

Factors that determine the best application method include:

- How quickly the project needs to be completed

- Curing

- Budget

- How thick the coating needs to be

- Overall appearance

- How durable the coating needs to be

We will further explore the metal coating types and the metal coating process below.

What Is the Purpose of Metal Coating?

Metal coatings help provide a protective layer for a variety of products, protecting them from the elements or other causes of wear and tear.

Increases Durability

When the coating is applied to the outer surface of an item, it, in turn, changes the surface properties of the item. If the item didn’t have the coating, it wouldn’t be nearly as durable or long-lasting.

Prevents Rust Formation

Specifically, metal coatings help to prevent oxidation and rust from occurring on the metal object. Liquids and chemicals can quickly take a toll on the durability and longevity of the product.

Increases Load-Bearing Capabilities

Not only do metal coatings help to provide a durable and corrosion-resistant layer to the product, but they can also increase the load-bearing capability of the product. This means that metal coatings can help increase the load-bearing capabilities in the products they’re on, allowing them to be used in a huge range of applications.

Minimizes Friction

The extra layer of coating provides a protective layer that prevents the amount of friction created between two moving parts. This is especially beneficial in protecting parts that require a ton of constant movement.

Eases Assembly and Disassembly

With the reduction in friction comes an easier time assembling and disassembling products from one another. This helps to simplify the cleanup process and eliminate any non-stick characteristics of the original product.

Metal Coating Process

There are four main ways in which metal coatings are applied to different surfaces, all of which we will cover below. The metal coating process may consist of hot-dip galvanizing, thermal spraying, electroplating, and sherardizing.

The type of coating process chosen oftentimes depends on the required thickness of the coating.

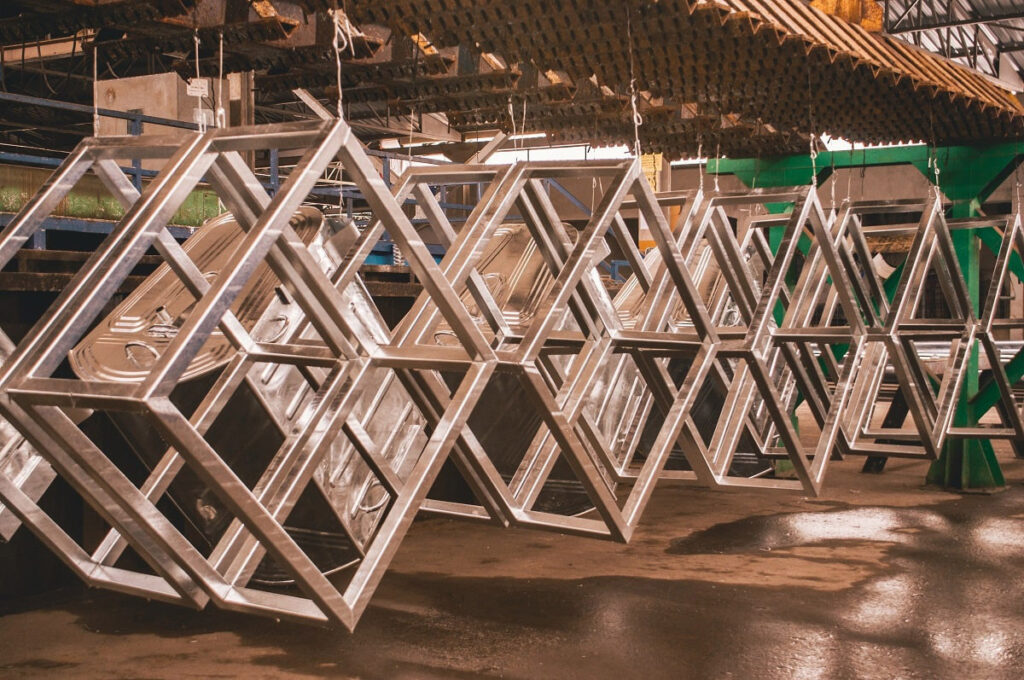

Hot-Dip Galvanizing

You can think of hot-dip galvanizing as a bath for the product being coated to ultimately form a corrosion-resistant layer of zinc-iron alloy and zinc metal. During hot-dip galvanizing, the steel component that is being coated is dipped into a pool of molten zinc that is at approximately 450 degrees Celsius.

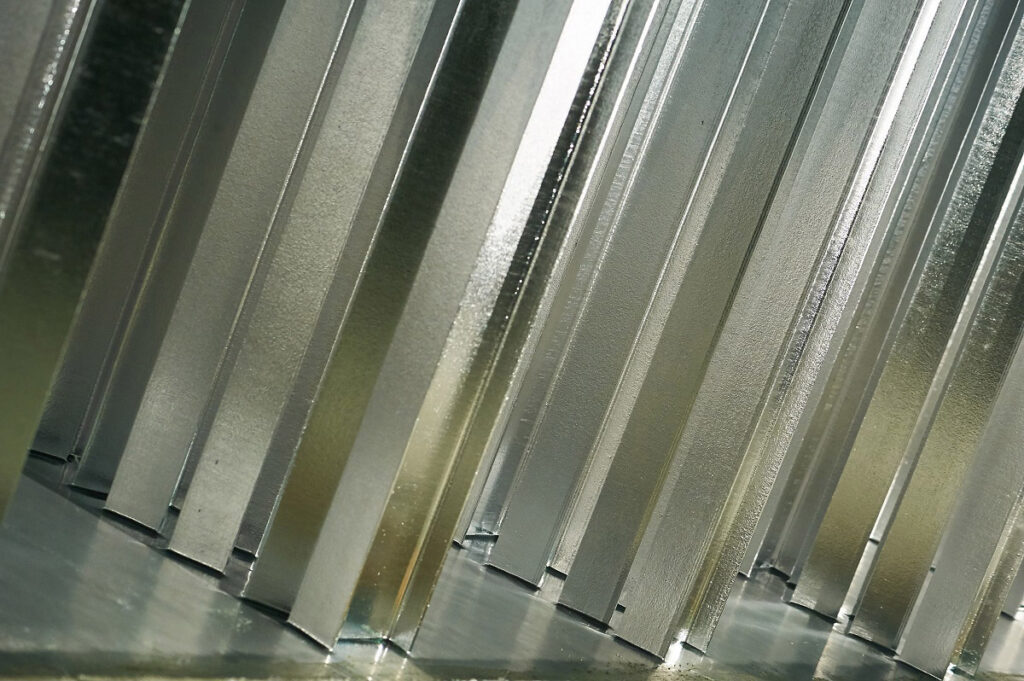

During the immersion process, there is a metallurgical reaction that takes place with zinc alloy and zinc layers. This reaction that takes place to coat the steel component is a diffusion process, helping to create a smooth, uniform layer of metal coating. The thickness of the metal coating is uniform throughout the piece as well.

Start with Surface Preparation

The first step in hot-dip galvanizing is to prepare the surface of the object or material being coated. Ideally, all oxides and contaminating residues will be removed from the surface beforehand to help create this metallurgical reaction. Without cleaning the surface beforehand, the reaction may not take place.

Preparing the surface isn’t a simple task, as the steel pieces being dipped can be quite large. They move through a series of cleaning steps using chains and wires.

- Degreasing is the first step. The steel is immersed in a degreasing bath to help remove contaminants such as oil, dirt, and grease that may be on the steel’s surface. Next, the steel is rinsed with water and ready for step two in the surface preparation process.

- Pickling comes next. This process consists of placing the steel in a dilute solution of other hydrochloric or sulfuric acid. During this process, all oxidation is removed from the steel and it is rinsed again for the final step.

- Fluxing is the last step. The flux layer helps ensure the steel is free from oxidation. A certain type of flux is housed in a separate tank, and it is slightly acidic. It is made from zinc chloride and ammonium chloride. Another flux variety may be used instead, and it is referred to as top flux. This variety serves the same purpose, but it floats in the galvanizing kettle on top of the liquid zinc.

As soon as all three steps in the surface preparation process are completed, the steel color will be close to a white color. It won’t have any oxides or contaminants and is ready to be galvanized.

Galvanizing the Steel

The zinc bath comes next, and the steel will be submerged in a galvanizing kettle. If there is a specific look in the coating that needs to be achieved, other metals are occasionally added during this step.

The kettle itself is heated to incredibly high temperatures, anywhere from 820-860 degrees Fahrenheit is ideal for ensuring the zinc is liquified. Next, the steel being coated is carefully dipped into the galvanizing kettle until it heats to the temperature of the bath.

As soon as the iron and zinc react with one another, the steel product being coated is withdrawn. The process as a whole takes 10 minutes or less, with exact timing dependent on how thick the steel piece is.

Post-Treatment Steps

After the piece has been removed from the kettle, the coating can further be enhanced through a process called quenching. There is a quench tank filled mostly with water, however, there are a few chemicals added to form a passivation layer. This layer protects the newly galvanized steel if it needs to be stored or transferred.

There are other finishing steps used besides quenching. Sometimes, there are small zinc drips or spikes that can form on the metal coating that needs to be ground off.

Thermal Spraying

The second metal coating process is called thermal spraying. It may also be referred to as spray welding, plasma spray, flame spray, metalizing, HVOF, and arc spray. All of these names are referring to the same thermal spraying process.

This process relies on a consistent heat source such as a flame as well as a coating material. The coating material is either in powder or wire form that is heated via the flame, resulting in small droplets that are sprayed onto the steel’s surface.

This type of coating cannot only be applied to metal substrates but some plastic substrates as well, as these coatings help to further improve the performance of the component being covered.

Thermal spraying may be used in place of other surface treatments such as nickel and chrome plating, weld overlay, heat treat processes, and anodizing. The results of thermal spraying are a bit thicker compared to other processes, with coatings anywhere from .002”-.025” thick.

There are four main thermal spray processes that we will outline below.

- Electric Wire Arc

This type of thermal spraying process is similar to the process used in wire arc welding systems. There is a wire coating material that is electrically charged. From there, it is contacted creating an arc while small molten droplets of metal wire are sprayed directly onto the substrate. This is achieved by using a high-velocity air stream to shoot the material out. Electric wire arc spray coatings are inexpensive and can be used for many different metals. Zinc, aluminum, copper, and even metal alloys such as stainless steel all react well to electric wire arc spray coating. This process also allows for changes to achieve the ideal coating thickness and texture. - Flame Spray

Flame spray is also referred to as acetylene combustion spray, and it is a technique that was developed over a century ago. It can be in either wire or powder form, and it mimics the process of using a welding torch, but it also can add a high-velocity air stream to further propel the substance onto the substrate. It’s not uncommon for flame spray coatings to fuse after they have been applied to increase the strength of the bond and to increase the coating density. - Plasma Spray

Plasma spraying is also referred to as a non-transferred arc, and it makes use of inert gas that is fed through an electrode. This induces the gas’s plasma state, allowing the gases to release from the gun apparatus and revert to their normal state. As you can imagine, a huge amount of heat is present for this to work. The coating material starts as a powder and as it is injected into the plasma flame, it is shot onto the substrate. Examples of plasma spray coatings include ceramic coatings as they have high melting temperatures. Ceramic coating examples include titanium oxide, aluminum oxide, chrome oxide, and zirconia. - High-Velocity Oxy-Fuel (HVOF)

The final process is HVOF, and it uses combusted oxygen combined with a group of ignitable gases such as hydrogen, propylene, or propane. This process uses the basic principles of combustion, however, there is a spray gun with a unique design. The HVOF spray gun is designed to produce both higher flame temperatures and higher velocities to create more kinetic energy. This added energy helps to produce an even stronger bond and create a stronger metal coating. This process is typically used for metals that have a high melting temperature such as chrome carbide or tungsten carbide.

Electroplating

The third metal coating process is called electroplating, also referred to as electrodeposition. This process revolves around an electric current that deposits the material onto the workpiece’s surface.

The current helps to dissolve metal and put it onto the surface using four main components:

- Anode: This is the name for the positively charged electrode.

- Cathode: This is the electroplating circuit that requires plating. The cathode is also called the substrate, as it will act as a negatively charged electrode while in the circuit.

- Solution: This contains at least one metal salt such as copper sulfate to help facilitate electrical flow.

- Power source: A power source adds the current to the circuit and is integral in adding electricity to the electroplating process.

As soon as the anode and cathode are connected, the power supply will begin adding DC, or direct current, to the anode. In return, the metal begins to oxidize and the atoms dissolve and turn into positive ions. The current then forces the move to the negatively charged substrate, resulting in a thin coating of metal.

Three factors may impact how high-quality the metal coating is. First is the bath conditions. The temperature of the bath and its chemical makeup must be just right to ensure the electroplating process is effective. Part placement is the second factor, as the farther the substrate is placed away from the cathode, the less effective the plating will be. The third factor is how high the electrical current is, as this will have an impact on how the electroplating process plays out.

There is a variety of benefits to using electroplating, including:

- Improved hardness of the substrate material to help extend their lifespan

- A cost-effective method of improving electrical conductivity

- Enhanced appearance for a more attractive look

- Protective barrier against environmental elements

Metals such as zinc, tin, copper, nickel, gold, silver, and palladium all use the electroplating process. The automotive industry, medical industry, electronics industry, aerospace industry, and oil and gas industry all use electroplating in a multitude of ways.

Sherardizing

Sherardizing also referred to as vapor galvanizing or dry galvanizing is a process that forms a protective layer of zinc-iron alloy on top of steel or iron. It has been practiced since approximately 1900 and it is named after Sherard O. Cowper-Coles, the inventor.

The object starts by getting heated in an airtight container with extremely high temperatures before it goes into a rotating drum. Next, a thermal diffusion process forces the zinc onto the surface of the metal, forming the zinc-iron alloy. The coating itself has a smooth surface and uniform thickness, providing a barrier against abrasion and corrosion.

The sherardizing process is especially ideal for coating small objects solely based on the type of uniform coating that it provides in addition to the limiting size of the container’s dimensions (2m x 5m x 4m). It is also ideal for geometrically complicated objects.

Examples of objects that commonly undergo sherardizing include rail track fittings, various cable hooks, metal fasteners, universal joints, or rubber bonding.

The adherent surface that results from the sherardizing process is ideal for:

- Painting

- Metal-to-rubber bonding

- Lubricants

- Organic coating applications

- Oils

- Sealants

Metal Coating Types

Different types of coatings are all used in certain situations. Here are the types of metal coatings.

Plastic Coatings

It’s possible to dip metal components into thermoplastic powders to create a protective coating. It is also referred to as fluidized bed dipping and it is one of the oldest types of plastic coatings that exists, dating back to 1952.

There is a thermoplastic coating that’s ground into a fine powder and stored in a fluid bed on top of a layer of fine gauze. The gauze helps ensure no particles are let through. Next, air flows through the gauze to allow the particles to rise and move around as fluid would.

To prepare the metal component for a plastic coating, it needs to be degreased and shot blasted. It can then be heated between 250-400 degrees Celsius while the exact temperature is dependent on the type of coating that’s required.

The metal piece can then be placed into the fluid bed while the plastic particles melt onto the metal. The result is a smooth, even plastic coating.

Paint Coatings

One of the most common ways to provide a protective steel layer is with paint. The paint’s quality and chemical makeup have evolved over the years to keep up with demands from bridge and building owners, as they needed paint that was durability and long-lasting.

The number of coats required is also decreasing thanks to this increase in paint quality and performance. What once required five or six coats of paint now only requires three coats or less.

To successfully paint over a metal coating, there are three steps involved in the process: priming, painting, and finishing. This helps form a “duplex” coating system with each layer providing a specific function.

Methods of applying the paint include roll coating, air-spraying, brushing, and electrostatic spraying. Weather conditions also have a significant impact on how well the paint coating lasts. Ideal results come from coats applied between 40-90 degrees Fahrenheit with a relative humidity between 40 and 70 percent.

As long as the proper protocols are followed, the right preparation is completed, and the conditions are ideal, the paint coating on metal structures should be able to withstand even the most extreme weather conditions.

Metal Coatings

Metal coatings can be applied to a variety of components to reduce the risk of corrosion and help the material last longer. There are four main types of metal coatings.

Zinc Coatings

This includes metallic zinc being applied to carbon steel through hot-dip galvanizing. The metal is immersed in the zinc to create a protective coating.

Aluminum Coatings

Both hot-dipped aluminum-silicon and hot-dipped pure aluminum are examples of aluminum coatings. Hot-dipped aluminum-silicon can resist heat up to 1250 degrees Fahrenheit and it has a heat reflectivity of 900 degrees Fahrenheit, meaning aluminum coatings are ideal for coating heat panels, shields, automobiles, and more.

Hot-dipped pure aluminum offers longer-lasting atmospheric corrosion protection. This type of metal coating is ideal for applications in the medical field, automotive industry, aerospace industry, and more.

Ion Plating

Ion plating is achieved through thermal evaporation. There are many processes involved to achieve ion plating, including electroplating, thermal evaporation, ion and atom sputtering, and ion implantation. Ion plating is ideal for coatings that fit unique and complex surfaces.

The Benefits of Metal Coating

Metal coatings offer important benefits that impact a variety of industries. Some highlights of metal coatings include:

- Minimize friction between two objects rubbing together

- Protection from potentially damaging chemicals

- Protection against rust, oxidation, and corrosion

- Helps ease assembly and disassembly processes

- Non-stick characteristics make the cleanup process easy and straightforward

- Increases the longevity in products

- Improves the appearance of products by eliminating flaws

- Overall cost savings

Conclusion

Look around you; chances are high that there is some sort of product or piece of equipment that has a metal coating on it. This is a highly popular and cost-effective method for your business to produce quality products that will last.

If you’re interested in learning more about metal coatings and how they can help play a role in the success of your business, our team at Schaumburg Specialties is more than happy to help. We provide hands-on assistance, impressive turnaround times, and quality welds that will last!

Contact us today at 855-929-1066 to tell us more about your upcoming project!