We know that many of our clients run production lines on a large scale and one of the biggest challenges they face is moving large quantities of food products around their premises safely, quickly and efficiently, to maintain a steady supply of ingredients across different stages of the process, minimize bottlenecks and ensure the smooth running of their operations.

Continue reading to learn how we custom built strong, sturdy pieces of equipment for two of America’s leading food production companies, to help ensure their manufacturing process consistently fires on all cylinders and meets the demands of their hungry customers!

Case Study 1: Dough Troughs For Highland Baking Co.

The Client

Since 1984 Highland Baking Co has been baking, fresh freezing and shipping hundreds of different bread products all over America – from hamburger buns, pan breads and pretzels to subs, ciabatta, table breads and dinner rolls.

The family business, now in its 2nd generation (and from a 5th generation baking family), has grown exponentially in the last two decades and now runs product ideation and development services as well as culinary immersion tours from its Culinary Innovation Center in Northbrook, IL.

The Challenge

Producing hundreds of different breads every day is no mean feat – and Highland needed to get hundreds of pounds of dough as well as finished product transported around its facility in a safe, speedy and efficient manner.

The dough needed to be moved in large quantities and at pace, to maintain a consistent and steady supply of ingredients across the different stages of its production line and keep the whole process running smoothly.

With so many products to manufacture, it was imperative that the equipment was able to accommodate large quantities, but it also had to be mobile and easy to maneuver and slot seamlessly into the company’s automated production line.

Of course, food safety regulations and hygiene security also had to be a top priority when manufacturing equipment for use in food production.

The Solution

Our expert team of design engineers and metal fabricators put their heads together and came up with the ideal, tailor made solution for Highland Baking.

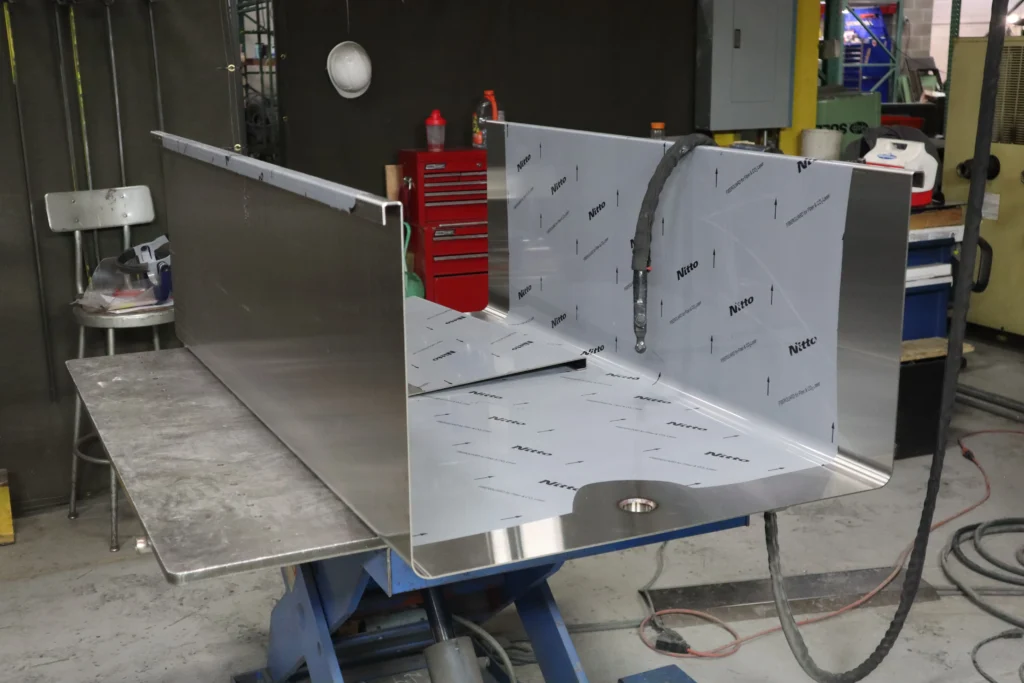

We built several sanitary stainless steel dough troughs that were approximately 67” long, 39” wide and 26” deep, with heavy duty casters. These troughs would easily be able to transport several hundred pounds of dough at a time around its facility, while the added feature of a sturdy handle would make manual maneuvering a breeze.

The troughs featured heavy duty casters & a sturdy handle

To enable the troughs to integrate seamlessly with Highland’s automated production line, we built each with a sidebar and two tubes underneath. This meant that the baking conveyor line could easily pick up the trough and tip dough out wherever it was needed on the production line. In addition, forklift trucks were able to scoop up the troughs with ease and transport them around Highland’s premises.

We built a sidebar and two tubes for each trough

Another great feature of the dough troughs was a sanitary port that was key to hygiene security. Having the port made it easy for Highland’s employees to drain any liquids or food residue away as well as allow water and cleaning agents to fully drain away after sanitation, in compliance with food safety standards.

We added a sanitary port

As soon as the dough troughs were ready, we shipped them to Highland Baking’s Northbrook, IL premises straightaway. They integrated quickly and smoothly into the company’s production line and our client was delighted with the results – so much so that we have made several more dough troughs for them since!

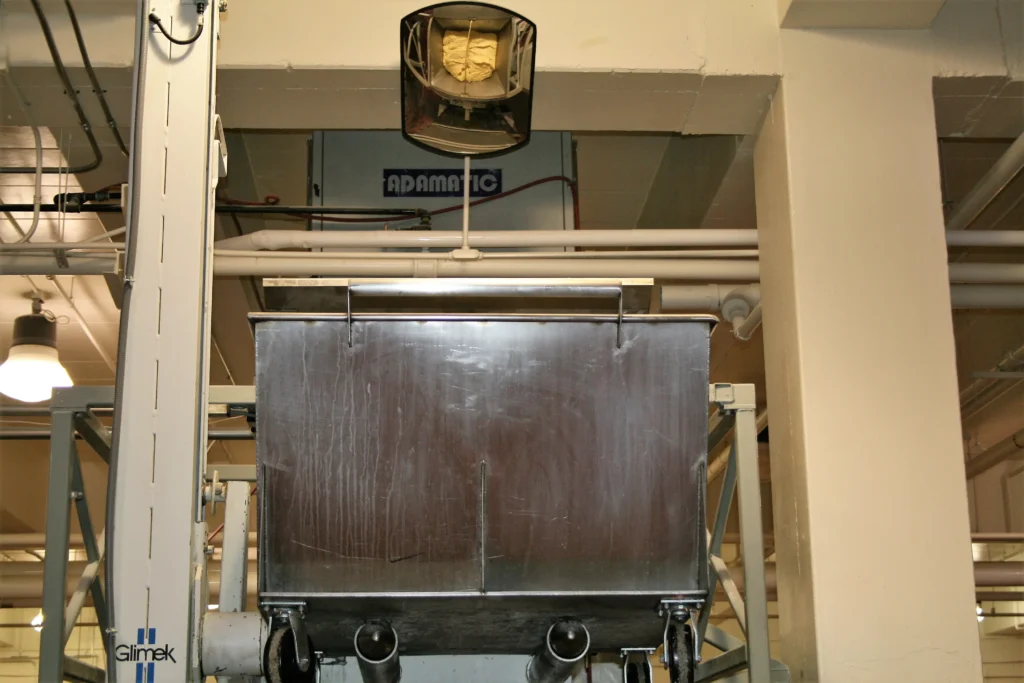

Dough troughs hard at work on Highland’s automated production line

Case Study 2: Bulk Tubs For America’s Top Prepared Meals Delivery Company

The Client

Founded in 2011, this private company provides fresh, chef-prepared meals directly to a customer’s door that can be heated and ready to eat in minutes.

Schaumburg Specialties has enjoyed a productive working relationship with the Chicago-based arm of the business since 2019, when it first started purchasing our standard aluminum pan racks – and we have been providing bulk orders of both single and double aluminum pan racks, as well as customized and custom built equipment such as bulk tubs for them ever since!

The Challenge

Like Highland Baking, this client’s challenge also revolved around the need to transport large quantities of ingredients and product around its premises safely with speed and efficiency and to keep its production process running like clockwork!

Offering over 40 flexible weekly menu options, as well as smoothies and supplements, to its many thousands of customers all over the country, it goes without saying that our client has a lot of ingredients and meals to prepare!

The Solution

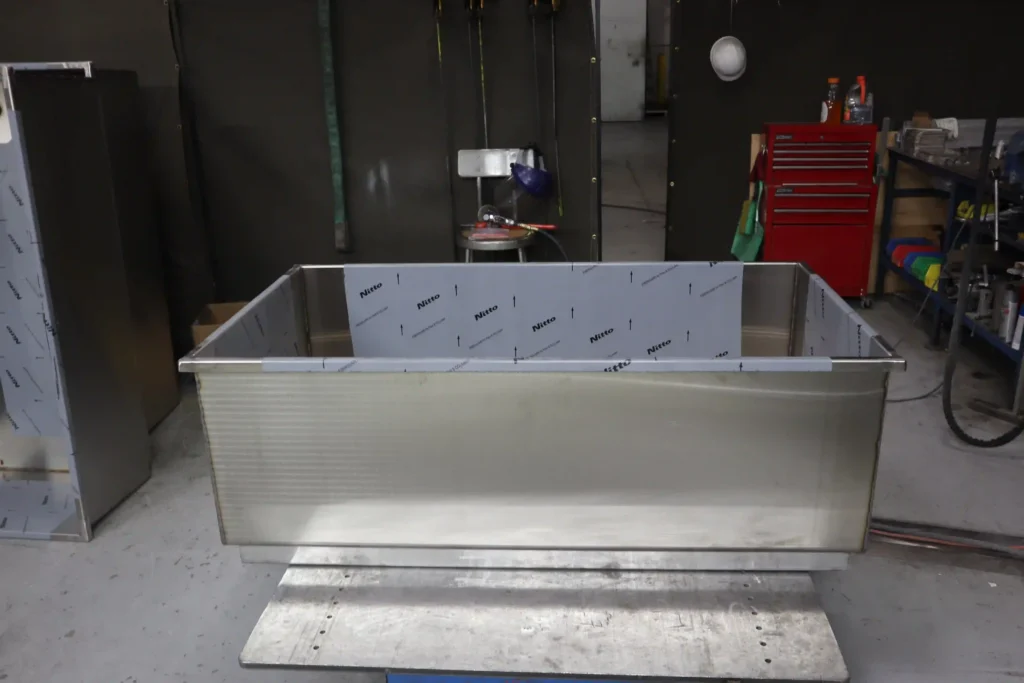

We built several full-welded tubs for our client that were ideal for moving bulk products such as sauces, soups and smoothies around its facility. Each tub measured 58” in length, 31” in width and 19” in depth and was fitted with four 6”x 2” polyolefin casters, to ensure easy and safe mobility and maneuvering, even in extreme hot or cold temperatures.

The fully welded tubs

For extra strength and durability and to enable solid, sturdy caster mounting, we also added sliders along the bottom length of each tub. This would also allow a forklift truck to pick up the tub with ease and move it around our client’s facility where needed.

We added sliders along the tub’s length

Naturally, the equipment we built also had to be food safe and compliant with the highest food safety standards, so we built the tubs using top quality, sanitary stainless steel and installed a drain valve on each that could facilitate the easy and hygienic draining of liquids, control the release of liquid ingredients between the different stages of production, as well as help control portion sizes and allow for the thorough washing, rinsing and sanitizing of the tub interior.

Each tub was fitted with a drain valve

As soon as the tubs were good to go, we dispatched and delivered them to our client’s facility where they got to work immediately helping prepare its hundreds of prepared meals recipes. The client was thrilled with the tubs and let us know that they were playing a crucial role in keeping production lines running smoothly and efficiently.

Since then, we’ve produced hundreds of stainless steel tubs for our customer (as well as many other pieces of custom made equipment) and we hope our fruitful business relationship continues for many years to come.

Get Started with Your Own Custom Project

We delivered awesome results for these customers and now we want to do the same for you!

If you have a custom build idea in mind or you have a specific production challenge that requires a tailor made solution, we’re here to help. To get started with your own project with Schaumburg Specialties, and to bring your design ideas to life, contact us so that we can get a clear understanding of your requirements. We’ll take it from there!