At Schaumburg Specialties, we have expert experience of metal fabrication and welding spanning 40 years – and rarely have we seen stainless steel rust! Stainless steel is actually well known for its resistance to rust – that’s why we use it to manufacture so much of the equipment in our iconic SHOPCraft, MEDICraft, INTELLICraft and AGRICraft ranges.

In fact, we have only seen stainless steel rust on one occasion and our own Eric Schaumburg even carried out a two-year experiment exposing a sheet of stainless steel to a saltwater solution – and it did not rust!

However, we cannot definitively say that stainless steel is completely immune to rusting. It’s one of those things in the world of metal fabrication – and indeed in the world at large – that occasionally occurs.

Read on to discover all the reasons why your stainless steel may be rusting, how to get rid of rust if it occurs and our top tips for caring for your stainless steel equipment….

Why Is My Stainless Steel Rusting?

As previously mentioned, stainless steel is well known for its strong resistance to rusting and that’s why we use it so extensively to fabricate strong, durable production equipment for the food, maritime, manufacturing and medical industries, among many others.

The resistance of stainless steel to rust is mainly due to the presence of chromium in the metal, which forms a thin, passive oxide layer on its surface. This oxide layer is composed primarily of chromium oxide and acts as a barrier that helps to prevent rusting occurring.

It also enhances the performance of stainless steel in various environments, especially harsh or corrosive ones, such as the maritime or chemical manufacturing industries. If this oxide layer is disrupted or compromised, then your stainless steel can become more vulnerable to rusting.

Here are some of the reasons why your stainless steel is rusting:

Low quality metal

Not all stainless steels are created equal and different metal grades contain different levels of rust-resistant chromium. Lower quality steels usually have less resistance to rust.

Contamination

There are many different types of steel and each one has its own properties that make it more – or less – prone to rusting. Carbon steel, for example, is highly prone to rusting, so if carbon migrates to your stainless steel somehow during the manufacturing process, and contaminates it, then your stainless steel is more likely to rust.

Exposure to harsh environments

The passive oxide layer that protects stainless steel from rusting can be broken down by exposure to harsh acids (especially at high temperatures) and chloride-containing environments such as saltwater in coastal areas and de-icing salts, used to melt snow and ice on sidewalks, roads and runways in wintery conditions.

Lack of oxygen

The chromium oxide layer that helps prevent your stainless steel rusting requires oxygen to maintain its protective properties. Where oxygen is limited, such as in tight, enclosed spaces or low-oxygen industrial environments, the oxide layer may break down and lead to localized rusting.

Surface Damage

Scratches or abrasions on the surface of your stainless steel can also disrupt its protective oxide layer. Such damage can expose the underlying material to the environment and make it more prone to rusting.

These are some of the reasons why your stainless steel may be experiencing rusting. Read on to find out how you can get rid of any rust that may have occurred and our top tips for preventing rusting on your stainless steel.

How To Get Rid Of Rust On Stainless Steel

Getting rid of the rust in your stainless steel is pretty much a case of grinding or sanding the metal’s surface down to get rid of the contaminants.

Depending on the extent of the rusting and the equipment to be treated, you can utilise anything from grinding machinery to an abrasive cloth such as sandpaper (which usually contains aluminum oxide grit) to get rid of rust.

If you want a gentler approach, you can try using an acetic acid/water or white vinegar/water solution on a non-abrasive cloth to remove any rust deposits.

Whichever method you choose, be sure to gradually remove the contaminants that are causing the rusting. In most cases, the contaminants and any rusting are on the surface of the metal and the integrity of the material below will not have been compromised.

How To Stop Stainless Steel Rusting: Our Top Tips

To prevent your stainless steel from rusting, there are several things you can try:

Choose the right grade of metal

It’s crucial that you choose the right grade of stainless steel for your specific application and working environment.

The baking and food industries, for example, as well as the marine and aerospace industries need a certain quality and grade of stainless steel to ensure that their equipment remains contaminant and rust free and can perform at the top of its game in a harsh environment.

At Schaumburg Specialties, we use only the highest quality metals to manufacture all our products. Talk to one of our experts today about your specific requirements.

Regular Cleaning and Maintenance

Regular cleaning and maintenance – as well as prompt removal of rust as soon as it appears using our methods above – can help safeguard your stainless steel equipment against contaminants and minimize the risk of rusting.

Clean your racks daily with a detergent or heavy duty oven cleaner (a baking soda and water solution would also work well). Make sure you dry your racks too, to ensure water deposits are not left behind to dry and form rust spots.

Regularly servicing and maintaining your equipment is also key to ensuring it remains rust-free and raring to go. Our servicing and maintenance program can help ensure an optimal performance for all your stainless steel and make sure it’s performing optimally, reliably and safely. Contact us today for more information and to book a consultation.

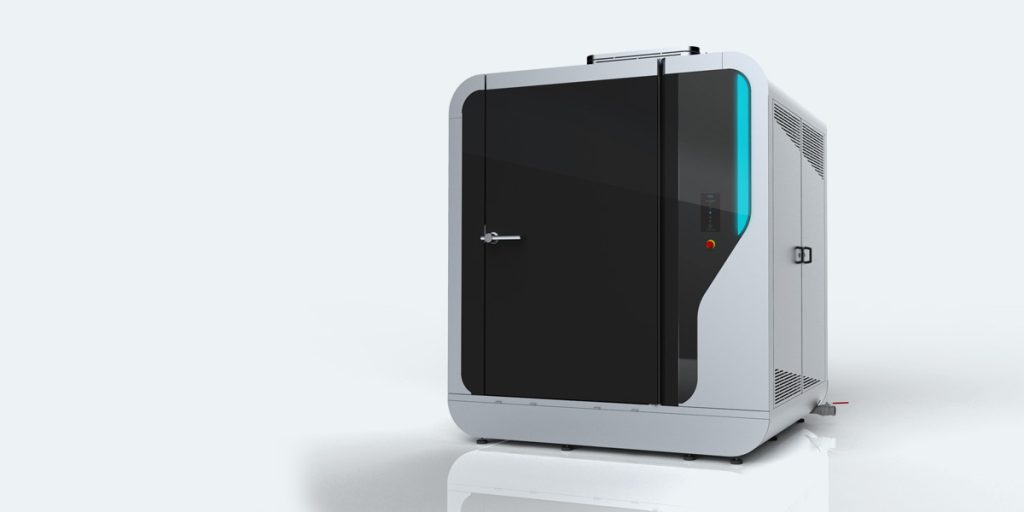

Invest in a Somengil MultiWasher

If you’re in the foodservice industry, an extremely easy way to ensure that your equipment is super clean, rust free and fully sanitized is to invest in a Somengil MultiWasher, available through Schaumburg Specialties.

Using this fabulous machine will transform your equipment cleaning processes – we guarantee you’ll never look back! Your racks will not only meet the very highest cleanliness and sanitation standards, they’ll also flash dry instantly when they’re taken out of the hot washer into room temperature, thereby preventing rust from forming.

Consider Passivation

Passivation – the process of cleaning surface contaminants from stainless steel and encouraging its protective oxide layer to come to the surface – can be essential for many of the industries that we work with, including food processing, pharmaceutical and aerospace.

Similar to the oxidation process that helps to build the corrosion resistance of aluminum, passivation helps maintain stainless steel’s resistance to rust and ensures that the metal performs reliably in harsh or corrosive environments.

However, please note that passivation should be carried out by trained professionals who can properly follow the safety guidelines for handling chemicals and the different regulatory procedures that apply for the treatment of different types of stainless steel alloys.

Invest in our Rust-Resistant Ranges

Of course, investing in well-made racks and carts such as those from our SHOPCraft, MEDICraft and INTELLICraft ranges means your equipment is extremely unlikely to rust in the first place.

Proper design and fabrication is crucial to ensuring rust-resistant stainless steel equipment – and at Schaumburg Specialties we’re well known for fabricating and producing the very best.

All the stainless steel equipment we design and build is made from premium quality metal that’s extremely strong and durable, so you’re highly unlikely to see any scratches, crevices, pitting or rusting occurring. It also comes with our famous Lifetime Guarantee, which means if anything untoward does occur that isn’t down to misuse, we’ll repair or replace it free of charge.

Contact us today to learn more and to place your order.