| Client: | Stella & Chewy’s |

| Industry: | Pet Food |

| Services: | Pet Food Manufacturing |

| Location: | Milwaukee, WI |

The Client

In 1997, Stella & Chewy’s founder, Marie Moody, adopted a dog named Stella from a local animal shelter. Shortly afterwards, she adopted a sick pup named Chewy as a companion for Stella – and so the story of Stella & Chewy’s began!

In 1997, Stella & Chewy’s founder, Marie Moody, adopted a dog named Stella from a local animal shelter. Shortly afterwards, she adopted a sick pup named Chewy as a companion for Stella – and so the story of Stella & Chewy’s began!

To help with his health issues, Marie took the advice of a veterinarian and began feeding Chewy a raw meat and vegetable diet. Both he and Stella thrived on their new food and such was the scale and speed of Chewy’s recovery Marie decided to pursue her passion for pet nutrition and start her own business.

From humble beginnings, working to compile recipes in her kitchen and delivering to her first clients out of the back of a taxi, Marie has built Stella & Chewy’s into the Number 1 freeze-dried, raw pet food manufacturer in the US! Its products are available in pet stores throughout the US and Canada, as well as globally (through distributors in Singapore, China, UAE and Republic Of South Korea).

The company has been a valued client of Schaumburg Specialties for many years, so when its team asked for our help to custom build strong, sturdy aluminum trays that it could rely on to withstand heavy use over time at its busy Milwaukee HQ, we were more than happy to oblige!

The Challenge

Stella & Chewy’s has an impressive portfolio of pet food, including freeze-dried raw food, wet food and dry food for cats and dogs. Its products are available throughout North America and Canada, as well as globally and online, so it’s safe to say that the company runs a very busy production line!

Its team approached our experts at Schaumburg Specialties because they were experiencing problems with the trays they used to put their pet food products on for drying and cooking.

The trays were flexing and warping and not staying flat, therefore they were unable to fit correctly onto the company’s pan racks (which were very dense, with only a 20mm gap between shelves) and perform optimally.

Stella & Chewy’s employees were finding it tricky to ensure that their products were being adequately contained and protected during the production process. This was all causing delays and inefficiencies and the team was finding it hard to keep up with the large demand for its products.

So they asked us to custom build 10,000 high-performing, strong and durable trays that were tailor made for the density of its racks’ shelving and for its conveyor line. The company also needed the new trays to get to work within a matter of weeks.

They asked if we could deliver 5,000 custom built trays that month and 5,000 the next month. Luckily, our talented team runs a very flexible production schedule, so we were able to expedite the order accordingly!

Our Solution

Our expert designers and welders designed and manufactured aluminum trays that were the perfect size and dimensions for our client’s unique requirements.

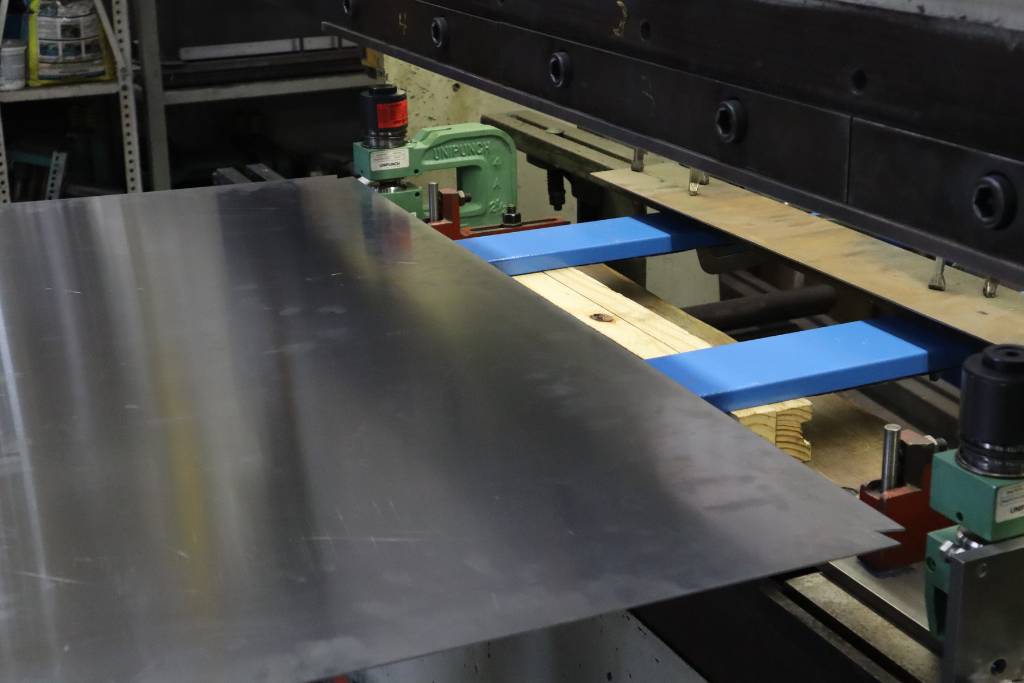

Cutting the metal to meet our client’s specific requirements

The trays that our team built were large – 2ft x 4ft and were manufactured from top quality American-made aluminum.

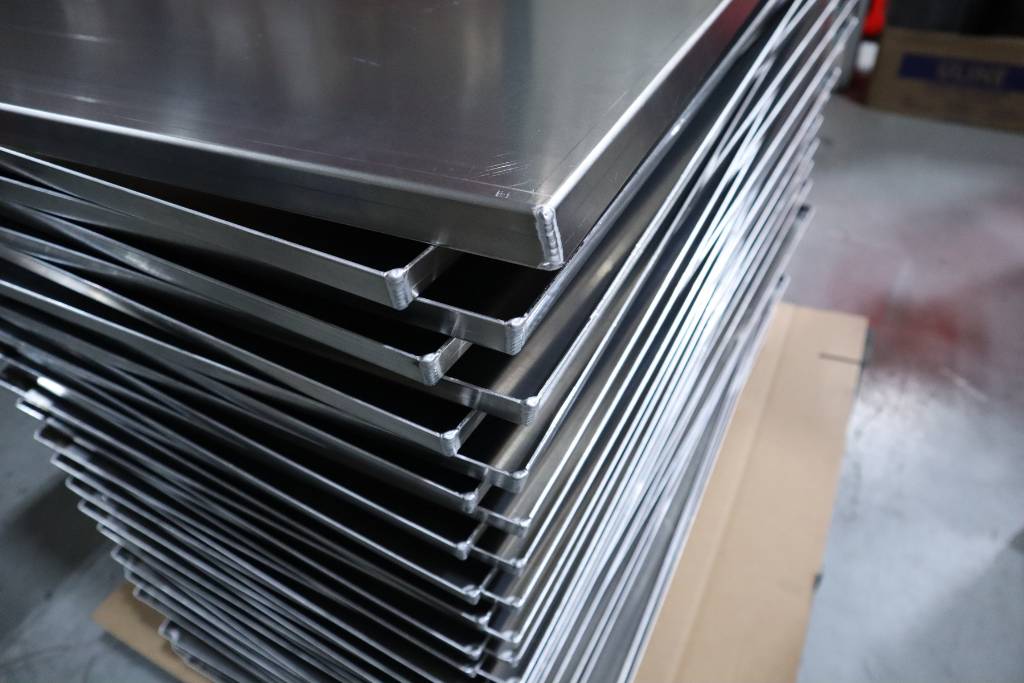

The custom built trays

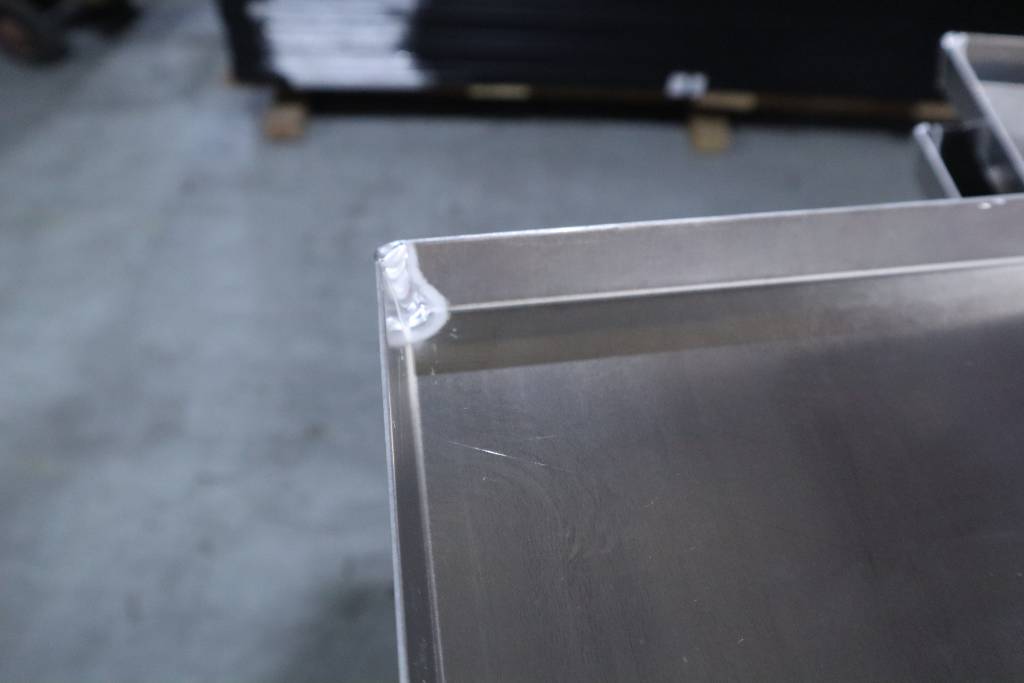

They also boasted welded corners, to maximize their strength, stability and durability, as well as help protect our client’s pet food products from dirt and debris.

The corners of each tray were welded

Once the trays were ready, we shipped them to Stella & Chewy’s facility, where they got to work straightaway on the company’s production line.

The trays ready to be shipped

We soon had feedback from our client that they were delighted with how well the trays were slotting perfectly into their racks (no warping!) and how well they were contributing to the plant’s hugely increased production efficiency.

Another day, another happy customer for Schaumburg Specialties!

Bring Your Custom Build Ideas To Life With Schaumburg Specialties!

We delivered awesome results for this customer and we want to do the same for you! Our design engineers and metal fabricators can custom build equipment that solves any and every production challenge and can adapt to any and all requirements!

To make your custom build vision a reality, contact us today!