| Client: | T. Marzetti |

| Industry: | Food Manufacturing |

| Services: | Manufacturer of specialty food products for retail and foodservice markets |

| Location: | Westerville, Ohio |

The Client

In 1896, Teresa Marzetti arrived in the United States with her husband Joseph and opened a small Italian restaurant in Columbus, Ohio.

Marzetti’s grew to be one of the finest dining experiences in the Midwest, but it was Teresa’s salad dressings that turned the company into a household name. Teresa turned the upstairs of her restaurant into a full-scale factory to make her dressings – and this formed the foundations of the business we know and love today!

T Marzetti is now a rapidly expanding manufacturer and marketer of specialty food products for the retail and foodservice markets and supplies many of the top restaurant chains in the United States. It works in collaboration with many large scale bakeries such as Cloud Boys Bakery to bring top quality products to dining tables across America.

Of course, when such a prestigious and valued customer asked us to build some unique racks in double quick time, we were only too happy to help!

The Challenge

Schaumburg Specialties has been custom building single sheet pan racks for T Marzetti for many years. This time, the brief was to custom build 32 single aluminum proofer racks for T Marzetti’s collaborator company, Cloud Boys Bakery, to help facilitate some new production processes at its Texas premises.

The big challenge with this project was the quick turnaround time. As a rapidly expanding business, T Marzetti – and specifically Cloud Boys Bakery – needed its new proof pan racks straight away, so it was a case of all hands on deck!

Another big part of our challenge was that it was necessary to make several adjustments to the racks to fit our client’s specific requirements during the manufacturing process. Not only that, but we were tasked with making those changes within the original one-week production time frame, for an expediting fee.

Luckily, our expert design engineers and welders were on standby at all times, ready to adapt their working processes to the needs of our customer and get the job done on time and to budget.

Our Solution

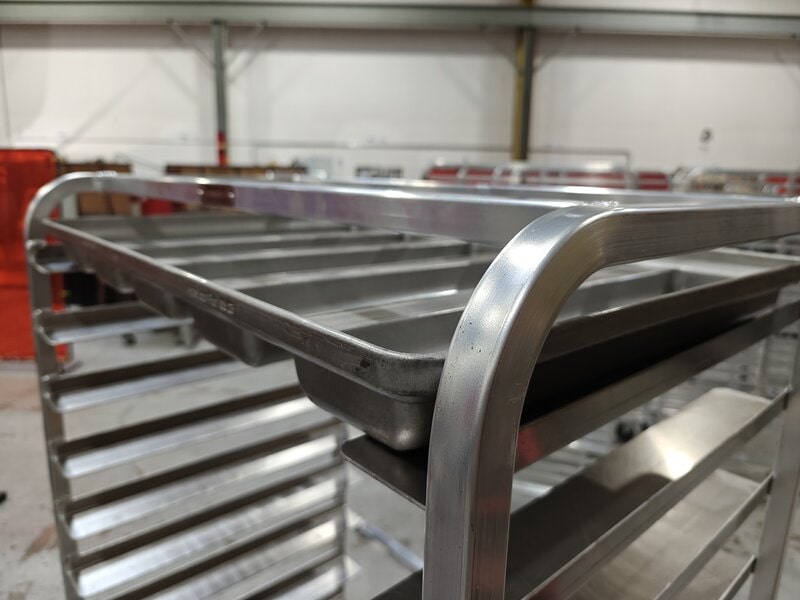

The initial drawings from our design engineers (for 32 aluminum side load racks of 15 levels with 4-inch spacing) were approved quickly and once we’d quoted for the job, we were given the go-ahead.

However, as we began to build the new proof racks, we received some feedback that the racks’ slides needed to be bigger, to hold the sheet pans in place more securely and prevent them (and any bread product!) falling down in between the rack levels.

So we modified our drawings to make the slides 2 inches wide rather than our standard 1.5 inches, to meet our client’s specific needs. These were approved and we began the build again, with the original one-week turnaround time still in play.

We modified the pan slides

When we had built three racks, we heard again from T Marzetti that it had some concerns about food safety and asked us to incorporate a welded top cover (to prevent any dirt or debris reaching food products from above) and a bottom cover (to prevent any splashing up of unsanitary liquid from below) into the racks design and build.

Of course, we stopped work right away, added the two new covers to the racks we’d already built and continued the build of the rest of the racks with the covers included.

Racks with top and bottom cover, ready for shipping

Once all 32 racks had been completed, we shipped them immediately to the Cloud Boys Bakery team in Texas and they got to work on its production line straight away!

And we soon heard that the client was delighted with how the racks are performing and that they’ve made a huge difference to their production efficiency.

The racks in situ at Cloud Boys Bakery

Another day, another happy customer for Schaumburg Specialties!

Our Lead Times Are Some Of The Shortest In The Industry!

We delivered awesome results for this customer in a very quick turnaround time – and we can do the same for you! Our expert design engineers and fabricators relish any production challenge and are ready and waiting to make your custom build vision a reality, in a time frame that suits you.