When it comes to providing premium quality equipment, the finish of a product can be just as important as the design and construction. To be top performing, efficient and durable, every single part of the product manufacturing process needs to be excellent – and that includes the finish!

At Schaumburg Specialties, we’ve been delivering top-tier finishing services, tailored specifically to meet the diverse needs of our valued clients, for over 40 years. Our finishing solutions – including deburring, polishing and industrial painting – are designed to improve the durability, aesthetics and functionality of your product and they both meet and exceed industry standards.

Whatever the product and whatever the application, you can always expect the highest quality finishing from Schaumburg Specialties.

Read on to discover more about the exceptional finishing services we provide and how they can enhance the quality of your product and the efficiency of your working operations.

Our Finishing Solutions

Deburring

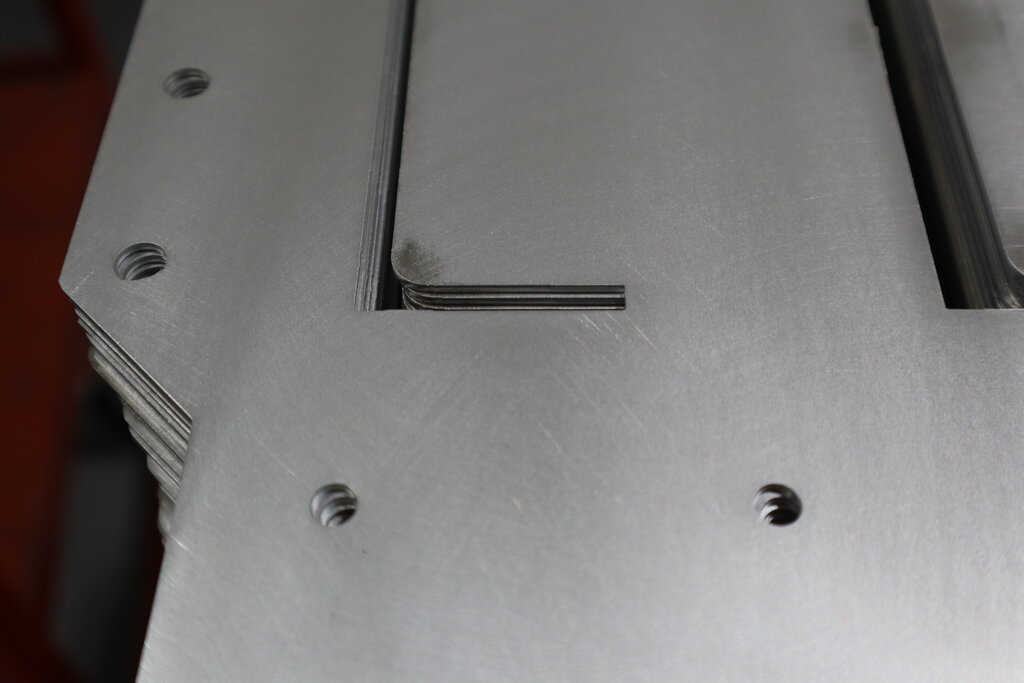

Deburring is the process by which the sharp edges (or burrs) are taken off (typically metal or plastic) products after fabrication or machining. Rough edges can affect the functionality, aesthetics, quality, and safety of equipment for workers and end users, making deburring an essential step in the manufacturing process.

Deburring makes rough edges smooth

At Schaumburg Specialties, deburring is a critical component of our finishing solutions and our manufacturing processes. At our plant in Schaumburg, IL, we use an edge finishing machine to remove all the sharp edges created during the production of our racks, carts, trollies, tables and other production equipment.

Sheet metal is fed into our deburring machine…

And comes out the other side with all sharp edges removed

We also use hand finishing techniques such as sanding and filing to complement the work of the edge finishing machine, to ensure a smooth and consistent finish. We like to go above and beyond and ensure that we are providing premium quality, high performing and aesthetically pleasing equipment to our customers.

Polishing

Polishing is a finishing process that removes the ridges and bumps that come with welding and fabricating metal. While deburring removes sharp edges, polishing smooths and enhances the surface of a material by rubbing it with an abrasive material, removing imperfections and enhancing aesthetics.

Particularly helpful in the food processing, pharmaceutical and healthcare industries, polishing helps close micro-pores on the surface of metals, which can reduce the risk of corrosion. Polished surfaces are also easier to clean and sterilize and less likely to harbor bacteria, thereby reducing the risk of contamination and ensuring compliance with the strictest hygiene standards.

A smoother surface can also minimize the areas where corrosive substances can accumulate, thereby enhancing the durability and lifespan of the material.

At Schaumburg Specialties, we use a variety of mechanical polishing techniques including buffing, grinding and sanding to achieve a premium quality, polished finish on all our custom built products. If you’d like to learn more about what we can do for you, please contact us to discuss a tailormade solution.

Polishing metal at our Schaumburg, IL HQ

Industrial Painting

Finding the right coating solution – and ensuring your product is properly coated!- is crucial for ensuring the durability, efficiency, and longevity of your production equipment. Whatever your application or the complexity of your project, our state-of-the-art industrial painting solutions have you covered.

Our spray paint booth is capable of handling projects both large and small and our staff have decades of experience in providing painting services of the highest standards and quality.

Industrial painting being carried out in our spray booth

Polyurea Spray Painting

If you’re looking for a coating technology that provides high durability and rust resistance as well as exceptional protection against a range of environmental and mechanical stresses, look no further than a polyurea finish.

Polyurea coatings are highly resistant to abrasion, impact, wear and tear, chemicals, oils, solvents and water. They work to maintain the integrity of your equipment and protect it from damage even in harsh conditions, as well as helping to extend its lifespan.

Their high resistance to moisture, corrosion and rust makes them ideal for use in the oil and gas, water treatment, and chemical processing industries, as well as in the marine and automotive industries, where they provide a strong, durable, non-slip coating for truck bed liners.

Despite their toughness, polyurea coatings are also extremely flexible, making them perfect coating for surfaces that experience frequent expansion and contraction due to temperature variations or structural loads – such as bridges, tunnels and parking lots and other critical infrastructure.

This flexibility also means they can be easily customized (by adjusting the formulation, thickness and application techniques) to meet specific performance requirements.

At Schaumburg Specialties, we’re experts in applying polyurea coatings to a variety of surfaces, including metal, concrete and wood and we’re experts at tailoring our polyurea spray finishes to the exact production needs of our clients. Get in touch with us today to see how our polyurea expertise can help your business.

Epoxy Coating

Epoxy coating is a rigid, high-strength coating that adheres to a variety of surfaces, providing exceptional protection against physical, chemical, and environmental factors.

Similarly to polyurea, epoxy coatings are renowned for their exceptional durability and high chemical, moisture and corrosion resistance. They are extensively used to protect metal structures, such as pipelines, tanks, and structural steel, from corrosion and environmental damage.

One standout property of epoxy coatings is that they are available in a variety of colors and decorative options, helping to enhance the visual appeal of your product and your brand image. From high-gloss and matte finishes to textured and decorative flakes, epoxy coatings offer customization options that can match the aesthetic requirements of any project.

Elastomer Spray Coating

At Schaumburg Specialties, we are authorized applicators of GatorHyde, a spray-on elastomer coating that offers superior protection for steel, fiberglass, concrete and wood surfaces.

Elastomer spray coating is a type of polymer-based coating that possesses elastic properties, allowing it to stretch and return to its original shape without cracking or losing adhesion. This makes them ideal for surfaces that experience movement, vibration, or thermal expansion and contraction.

Elastomer coatings are applied as a liquid that cures into a seamless, flexible membrane that offers excellent protection and durability, helping to extend the longevity of your equipment.

Our team of experts is well versed in all the industrial painting finishing solutions that we offer. If you have any questions at all, please contact us to discuss the coating that would best suit your requirements.

Find Your Perfect Coating Solution With Schaumburg Specialties

Here at Schaumburg Specialties, your productivity is our passion. Regardless of your application or the size and complexity of your project, our team of finishing experts will work with you to find a coating solution that will enhance the functionality, durability and aesthetics of your equipment and the efficiency and productivity of your business.

To find out more about how we can help, contact us for a free quote.